Journal of the NACAA

ISSN 2158-9429

Volume 5, Issue 2 - December, 2012

Production practices and challenges with high tunnel systems in Maine

- Fitzgerald, C.B., Extension Educator and Assistant Extension Professor, University Of Maine Cooperative Extension

Hutton, M., Extension Specialist and Associate Professor of Vegetable Crops, University of Maine Cooperative Extension

ABSTRACT

This study of 52 high tunnels on 31 Maine farms identifies areas where additional or continued education with high tunnel farmers is needed. This includes site selection and preparation, design and management of drip irrigation systems, using soil tests, timing of manure and compost applications, and awareness of the increased labor need resulting from the addition of a high tunnel. The study also provides benchmark data about construction, management, and cropping practices in Maine high tunnels. Comparisons of harvest season length, pests, income, and yield between tunnel- and field-grown tomatoes, peppers, and cucumbers were also made.

Introduction

In the United States, farmers are increasingly interested in learning about and adopting high tunnel technology to extend the growing season and protect crops (Carey et al., 2009). Benefits of high tunnels include higher daytime temperature, greater growing degree days, and faster crop maturity (Waterer and Bantle, 2000); higher nighttime temperatures that help warm-season crops escape early or late frosts (Waterer, 2003; Waterer and Bantle, 2000; Wien, 2009); and the capacity to produce crops or varieties that are not feasible or reliable in open field production (Wildung and Johnson, 2010a). Other advantages to using a high tunnel include greater and more predictable yield, higher quality, and protection from wind, rain, hail, and insects (Wittwer, 1993; Wien and Pritts, 2009).

New high tunnel farmers have many construction and management resources available. These include advice about choosing a tunnel style, preparing the site, and building end walls, as well as management practices such as mulches, irrigation, and fertilization (Huntrods, 2010; Jett et al., 2004; Blomgren and Frisch, 2007; Pennsylvania State Univ., Dept. of Horticulture, 2003). Even so, tunnel production practices can be highly variable, in part reflecting the diversity of crop types, timing, and production systems in the tunnels (Montri and Biernbaum, 2009).

This study was designed to:

1. collect benchmark data on the construction, management, and cropping practices in Maine high tunnels;

2. estimate the benefits and detriments of high tunnel production compared to open field production with respect to pests, labor management, yield, and income;

3. identify production challenges for high tunnel farmers, which we expected might include time management managing a large diversity of crops.

Materials and methods

Between June 2011 and March 2012, three sequential surveys were conducted with 31 farmers from across Maine to collect information about their high tunnel use. The first two surveys were conducted in person on the farm between 9 June and 10 August and from 15 August to 3 October. The final survey was conducted in person or by phone beginning 24 October 2011 and ending 5 March 2012. There were at least 28 days between successive surveys with each farmer. The surveys included 49-73 standard questions, were administered by one of three project personnel, and took from 20 – 90 minutes to administer. Follow-up questions were asked at the interviewer’s discretion. Interviewers noted observable aspects of the structures and crops.

Sixteen of the farmers had received Natural Resource Conservation Service (NRCS) funding to purchase a high tunnel, and they agreed to have their contact information shared in order to participate in the study. These farmers managed 40% of the tunnels in the study. The NRCS selection criteria for tunnel funding dictated that the farmers could not already have a commercially-designed high tunnel on the farm. Therefore, most in this group were new to growing crops in high tunnels. The researchers and Cooperative Extension colleagues identified a group of experienced high tunnel farmers who were invited to join the study. The fifteen who agreed to join managed 60% of the tunnels in the study.

Basic data was collected for one or more high tunnels per farm for a total of 52 tunnels. More detailed data was collected from one tunnel per farm as part of a focus study. On farms with multiple tunnels, the one used in the focus study was the one funded by NRCS. If none was funded by NRCS, the farmer chose a representative tunnel that was used to grow tomatoes, if this crop was grown.

When farmers were asked about dates that crops were available to sell, they often reported a timeframe within a month, rather than a specific date. General dates within a month were standardized as follows: “first of,” “early in,” or “first week of” = 3rd of the month; “second week” = 10th; “mid-month” = 15th; “third week” = 24th; “end of” = 28th.

Despite standard survey methods, the number of responses varied from question to question. In some cases, farmers chose to not answer certain questions, did not have the data, or did not have enough time to answer all the questions. The last is a drawback to surveys conducted during the growing season. Where possible, we tried to get the information at another interview or by email. Four farmers were not reachable in time or at all for a final interview.

Results and discussion

Farmer production experience and markets

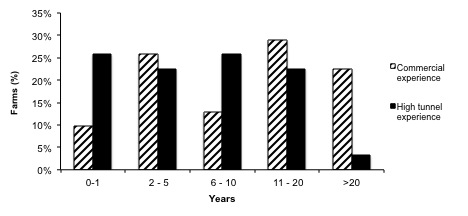

Commercial farming experience among the group surveyed varied from less than one year to more than 20 years of growing crops either in a field production system or in high tunnels (Figure 1). All farmers were equally or less experienced with high tunnel production compared to field production. Twenty-six percent of the 31 farmers surveyed had National Organic Program (NOP) certified organic high tunnels.

Figure 1. Number of years of general commercial farming experience and years of experience using high tunnels for the 31 farmers participating in the 2011 high tunnel survey.

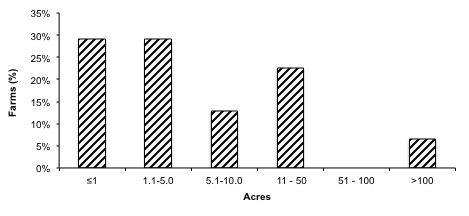

All farmers grew similar types of horticultural crops (mixed vegetables, cut flowers, small fruit, tree fruit) uncovered in the field as they did in the high tunnel. Fifty-eight percent of farms had 5 acres or less in crops being grown in both systems (Figure 2).

Figure 2. Number of acres in commercial production of the 31 farms in Maine participating in the 2011 high tunnel survey.

Seventy-one percent of farmers used direct-to-consumer outlets such as farmers’ markets, farm stands, or community supported agriculture (CSA) as their primary market outlet. Only 32% participated in a year-round market that could accommodate fresh, tunnel-grown products (data not shown).

High tunnel characteristics and construction

The physical characteristics of the high tunnels in this study are listed in Table 1. The preference for gothic style reflects the engineering needed to withstand Maine’s winter weather. Three tunnels were designed for spring, summer, and fall use only, with the plastic removed in the late fall.

|

Survey topic |

Summarized responses (%) |

Total responses (no.) |

|

Tunnel style |

Gothic (87%), quonset (13%) |

52 |

|

Manufacturer |

Ledgewood (38%), Rimol (21%), Homemade (13%), Griffen (8%), Farmtech (6%), Haygrove (6%), Harnois (2%), Golden Pacific (2%) |

52 |

| Tunnel age |

less than 1 year (11%), 1 year (42%), 2 years (11%), 3 years (2%), 4 years (9%), 5 years (9%), 6 years (4%), 7 years (4%), 8 years (4%), 9 years (0), 10 years (0), 11 years (0), 12 years (2%) |

45 |

| Orientation | East-West (58%), North-South (38%), Northeast-Southwest (4%) | 52 |

| Rating of general tunnel conditionz | Excellent (35%), very good (40%), good (19%), fair (6%), poor (0) | 48 |

| Cover--single or doubley | Single (75%), double (25%) | 52 |

| Cover age (years) | 1 (63%), 2 (21%), 3 (2%), 4 (4%), 5 (4%), 6 (4%), 7 (2%) | 48 |

| End wall frame | Wood (87%), metal (13%) | 52 |

| End wall cover | Wood (13%), plastic (65%), Polycarbonate (15%), combination (6%) | 52 |

| Access doors, type and number |

Equipment door only: 1 (2%), 2 (40%); man door only: 1 (29%), 2 (10%); 1 equipment door and 1 man door (10%); 2 equipment doors and 1 man door (8%) |

48 |

| Side venting | Roll up (81%), push up (8%), push up and tie (4%), roll down (0%), none (8%) |

52 |

| At least one gable vent | Yes (21%), no (79%) |

52 |

| Tunnel built on raised pad | Yes (4%), no (96%) | 52 |

| Drainage installed | Yes (19%), no (81%) |

52 |

zHigh tunnels that were rated in good or fair condition had torn plastic on the end walls or the sides, cloudy plastic needing to be changed, considerable air gaps at corners and doors, or temporary venting provided by cutting plastic.

yNRCS-funded tunnels could not have double-layer, inflated plastic.

Table 1. Physical characteristics of high tunnels on 31 farms in Maine during 2011.

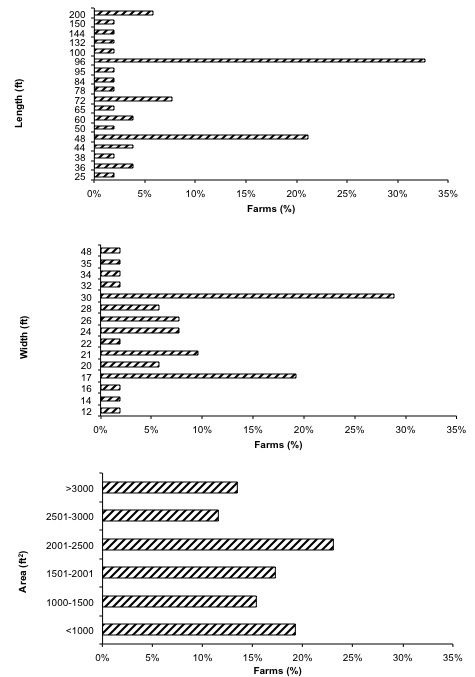

Tunnel dimensions and area were highly variable from farm to farm (Figure 3). The most common lengths were 96 ft. followed by 48 ft., and the most common widths were 30 or 17 ft. These are similar to the dimensions reported by Knewtson et al. (2010). The 2010 NRCS program had a payment cap of $2.57 per ft2 and a cap area of 2178 ft2. Forty-seven percent of the NRCS-funded tunnels exceeded the size cap for full funding, and the farmers made up the difference in cost

Figure 3. Dimensions and area of high tunnels located on 31 Maine farms surveyed in 2011.

High tunnel manuals stress the importance of good site selection, diverting runoff, and remedying drainage problems prior to construction (Wildung and Johnson, 2010b; Blomgren and Frisch, 2007; Jett et al., 2004). In this study, farmers performed site work to mitigate potential soil drainage problems prior to construction at 23% of tunnel sites. Sixteen percent of tunnels (including one tunnel receiving pre-construction drainage work) required post-construction efforts to address drainage problems. The problems were caused by runoff from upslope areas, water and ice accumulation in the winter, or inherently poor soil drainage within the tunnel. Although proper site selection and preparation is emphasized in high tunnel literature and educational programs, it is clear that more emphasis is needed.

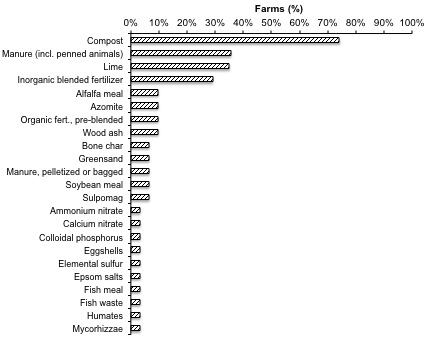

High tunnel management

Table 2 and Figure 4 summarize the crop management practices used in the study high tunnels. An assortment of soil amendments was applied to the 31 tunnels in the focus study from fall 2010 to late summer 2011 (Figure 4). Reflecting management practices seen in other areas of the United States (Montri and Biernbaum, 2009; Knewtson et al., 2010), compost and/or animal manure (including the use of animals penned inside the tunnel) was used in 94% of the tunnels. Only 36% of tunnels in the focus study received additional nutrients through fertigation.

| Survey topic | Summarized responses (%) | Total responses (no.) |

| Fertigation use and materials in focus study tunnels | Yes, organic materials (13%), yes, non-organic materials (23%), yes, both organic and non-organic materials (3%), no fertigation (61%) |

31 |

| Primary tillage method for 2011 season | Rototiller, not tractor-mounted (54%), rototiller, tractor-mounted (38%), hand tools (8%) | 39 |

| Ground cover within crop rows | Landscape fabric (40%), plastic mulch (33%), leaf litterz (2%), none (26%) | 43 |

| Ground cover between crop rows | Landscape fabric (49%), plastic (9%), straw (5%), hay (2%), bark mulch (2%), cardboard (2%), combination (leaf litterzand straw) (2%), none (28%) | 43 |

| Irrigation method in the tunnels | Drip (61%), overhead (17%), hand (12%), none (10%) | 41 |

| Crops grown in winter 2010/2011 | Yes (38%), no (62%) | 46 |

zLeaf litter was partially-decayed leaves collected from a wooded area.

Table 2. Crop management practices used by 31 Maine farmers in high tunnels, 2011.

Figure 4. Nutrient sources used between fall, 2010 and spring, 2011 on 31 Maine high tunnels included in focus study.

Forty-two percent of farmers used “aged” manure or homemade compost in their tunnels without appearing to follow either recommended compost production methods (Rangarajan et al., n.d.) or the recommended 120-day waiting period between raw manure application and crop harvest (Rangarajan et al., 2000). While farmers are not required to follow these best management practices unless they are participating in a certification program that requires it, additional education will reduce food safety risks to consumers.

We were surprised that farmers reported taking soil tests on only 48% of the focus study tunnels (n=29, data not shown). Soil testing is a simple, inexpensive tool to ensure adequate soil fertility for the high-value crops grown in the tunnel. It is also a good monitoring tool to watch for adverse salt or nutrient accumulations that can develop when using large amounts of compost or manure (Montri and Biernbaum, 2009; Reeve and Drost, 2012). The benefit of regular soil testing should be stressed with both new and experienced farmers.

Sixty-one percent of tunnels (managed by 68% of farmers) included drip irrigation. It was interesting to note that drip irrigation was a new technology for nearly half the farmers, since only 23% used it in the field. Maine’s typical weather and rainfall does not require supplemental irrigation for good crop growth in many years.

Sixteen percent of farmers, including some using trickle irrigation for the first time, reported challenges supplying enough water to crops in the tunnel. These challenges were caused by difficulty learning to install and use a new trickle irrigation system, not having a well drilled in time, using expensive municipal water, or struggling to meet all the farm’s water demands with an insufficient water supply. Several of these farms were also not using mulches inside the tunnel, which can help with conservation of soil moisture. Educational programs about irrigation system planning, design, and use would be very helpful for new tunnel farmers in Maine and in other areas where supplemental irrigation is not always used.

High tunnel crops

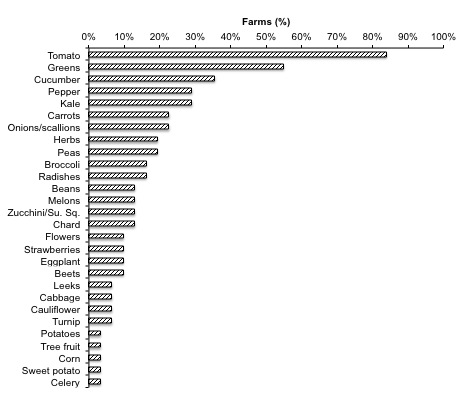

We observed 26 different crop types being grown in the focus study tunnels during the summer of 2011 (Figure 5). Tomatoes and greens (including lettuce, spinach, and others) were the most common crops grown, as was found in other studies (Knewtson et al., 2010; Carey et al., 2009; Wien and Pritts, 2009). Fruits and cut flowers were of secondary importance.

Figure 5. Crops grown in the summer of 2011 in 31 Maine high tunnels included in focus study.

Between June and August, 55% of tunnels were used to grow only one or two crops (data not shown). Forty-two percent were used to grow three or more crops, including one tunnel that had 14 crop types in production. One tunnel was not used for summer production. We had expected that the newer tunnel farmer would be the ones with more diverse production in the tunnels. Instead, diversity seemed to be related to overall farm size and thus market size. Tunnels located on smaller farms tended to have more than two different species growing simultaneously in the summer, while larger farms tended to have only one or two species growing simultaneously.

Only 38% of tunnels were used to grow annual crops during the winter (Table 2). This was expected, since most farmers did not have a year-round market for fresh, tunnel-grown products. Knewtson et al. (2010) and Waldman et al. (2012) also found winter production to be of secondary interest compared to warm-season crop production.

Farmers reported that they were reluctant to rotate crops in their tunnels because they want to continue growing their most profitable crop, typically tomatoes. Of the 21 tunnels with two summers of crop data available, 62% were used to grow tomatoes or other solanaceous crops in both years (data not shown). Although non-solanaceous winter crops, including cover crops, were present in some tunnels, the lack of rotation of summer crops increases the likelihood of soil-borne diseases and some foliar diseases in the tunnel (Mohler and Johnson, 2009). However, the impact was not determined in this study.

Comparing labor needs, high tunnel vs. open field

Seventy-eight percent of respondents (n=18, data not shown) reported that more labor was needed to manage a similar square footage of the same crop in the high tunnel than in the field. Factors reported as contributing to the higher labor needs included increased harvest frequency and the large amount of hand work needed, such as pruning and trellising tomatoes, managing the ventilation and irrigation/fertigation, and managing pests. Despite these higher labor demands, only 28% of respondents reported that they were decreasing the acreage of field-grown crops as a result of having a high tunnel. Conner et al. (2010) observed a similar pattern, reporting that a high tunnel seemed to increase the overall summer workload on the farm rather than shifting labor needs to the spring and fall. Farmers need to be advised of these increased labor and management demands as they are considering installing a high tunnel.

Some positive labor effects were noted. Forty percent of respondents (n=31, data not shown) specifically stated that the high tunnel allowed for efficient labor use since it was a convenient place to work in bad weather. Farmers reported that less time was required to wash, grade, and prepare crops for market when harvested from high tunnels. Some high tunnel farmers also noted that they were under less pressure to plant field crops by a particular date in the spring if the same crops were already growing in the tunnel.

Comparing crop production, high tunnel vs. open field

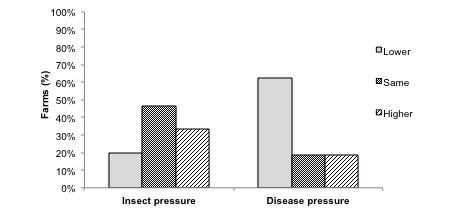

Using a five-point scale ranging from no pest pressure to high pressure, farmers provided ratings of disease and insect pressure for both tunnel- and open field-grown tomatoes between August and October (Figure 6). Sixty-three percent of farmers (n=16) reported less disease pressure in the high tunnels, specifically noting lower levels of early blight (Alternaria solani) and late blight (Phytophthora infestans). Farmers who reported greater disease pressure in the tunnels reported the cause as Botrytis cinerea or an unspecified disease. Nearly half (47%, n=15) of the farmers reported similar insect pressure in tomatoes grown in the tunnels as compared to those grown in the field. Using a similar five-point scale to rate the quality of tunnel- and field-grown tomatoes, fifty-six percent of farmers (n=18) reported higher quality tomatoes from their high tunnel compared to those grown in the field (data not shown).

Figure 6. Comparison of tomato insect and disease pressure in high tunnels and in the open field on Maine farms surveyed, 2011.

Farmers reported the dates that they had sufficient numbers of tomatoes, peppers, and cucumbers available for marketing from all high tunnels on the farm. Across all farms, the reported marketable harvest dates were, on average, a month earlier and a month later from high tunnels than from the field for all three crops (Table 3). These results are consistent with two years of study in Minnesota (Wildung and Johnson, 2010a). Early product availability is likely to translate into higher market prices (Cheng and Uva, 2008). Additionally, season extension may allow Maine farmers to produce crops that the short season does not allow in an uncovered system, as in the case of one who was able to harvest colored peppers from the tunnels, but not from his field-grown peppers.

| Location | Crop | First harvest | Final harvest | Days of market availabilityz | |

| High tunnel | |||||

| Tomato | 10-Jun | 21-Nov | 164 | ||

| Pepper | 15-Jun | 15-Nov | 153 | ||

| Cucumber | 10-Jun | 5-Oct | 117 | ||

| Open Field | |||||

| Tomato | 15-Jul | 15-Oct | 92 | ||

| Pepper | 15-Jul | 15-Oct | 92 | ||

| Cucumber | 3-Jul | 15-Sep | 74 | ||

zDays of market availability is total range across all farms.

Table 3. Date of first and final harvests of crops grown and length of the marketing season in both high tunnels and open fields located in Maine, 2011.

Some farmers provided estimates of per-plant yield and gross income differences between crops grown in high tunnels and those grown in the field (data not shown). Nine farmers reported from 25 to 250% higher tomato yield from their high tunnels. Five farmers reported from 50 – 300% higher gross income from the high tunnel tomatoes compared to those grown in the open field. Farmers also reported higher yield and/or gross income for peppers (3 farmers), cucumbers (3 farmers), and greens (4 farmers). No farmers reported lower yields or income from tunnel crops compared to those grown in the open field. Although these results are limited and general, they do support other reported results (Wildung and Johnson, 2010a).

Overall satisfaction

Overall, most farmers in this study reported that having a high tunnel had met their expectations. The most-cited advantages to tunnel production over open-field production were improved quality, timing (including early-season, late-season, and winter production), labor use in poor weather, and yield. Some farmers commented that high tunnels were essential to their business, because of the crops they could now produce or the markets they could supply. Sixty-one percent of farmers (n=23) reported that they plan to add another high tunnel or other protected structure, and an additional 17% are considering doing so (data not shown).

Conclusion

High tunnels can provide important production and marketing improvements for farmers, thereby potentially increasing farm profit. However, there are challenges to adopting this technology. Through farmer surveys, this study identified five particular areas where additional education is needed. Site selection and preparation, compost and manure use, soil testing, and awareness of increased labor needs are topics that would be applicable to farmers and Extension programs in all areas of the country. In areas with limited use of trickle irrigation in the field (as in Maine), programs about this particular technology would also be useful for high tunnel farmers. This study’s benchmark data about structure type, management, and yield benefits should be applicable in other northern areas.

Literature Cited

Blomgren, T. and T. Frisch. (2007). High tunnels: Using low-cost technology to increase yields, improve quality and extend the season. University of Vermont Center for Sustainable Agriculture. Retrieved from http://www.uvm.edu/sustainableagriculture/hightunnels.html

Carey, E.E., L. Jett, W.J. Lamont, T.T. Nennich, M.D. Orzolek, and K.A. Williams. (2009). Horticultural crop production in high tunnels in the United States: A snapshot. HortTechnology 19:37-43.

Cheng, M. and W. Uva. (2008). Removing barriers to increase high tunnel production of horticultural commodities in New York. Cornell University. Retrieved from <http://www.hort.cornell.edu/hightunnel/about/research/economics/removing_barriers_uva_cheng.pdf

Conner, D.S., K.B. Waldman, A.D. Montri, M.W. Hamm, and J.A. Biernbaum. (2010). Hoophouse contributions to economic viability: Nine Michigan case studies. HortTechnology 20: 877-884.

Huntrods, D., ed. (2010). Iowa high tunnel fruit and vegetable production manual. PM 2098. Iowa State University, University Extension. Retrieved from <http://www.extension.iastate.edu/Publications/PM2098.pdf

Jett, L.W., D. Coltrain, J. Chism, J. Quinn, and A. Read. (2004). High tunnel tomato production. University of Missouri Extension M170. University of Missouri. Retrieved from http://extension.missouri.edu/explorepdf/manuals/m00170.pdf

Knewtson, S.J.B., E.E. Cary, and M. B. Kirkham. (2010). Management practices of growers using high tunnels in the Central Great Plains of the United States. HortTechnology 20:639-645.

Mohler, C.L. and S.E. Johnson (Eds.). (2009). Crop rotation on organic farms. A planning manual. NRAES-177. Ithaca, NY: Natural Resource, Agriculture, and Engineering Service (NRAES).

Montri, A. and J.A. Biernbaum. (2009). Management of the soil environment in high tunnels. HortTechnology 19:34-36.

Pennsylvania State Univ., Dept. of Horticulture. (2003). High tunnel production manual. University Park, PA: The Pennsylvania State University.

Rangarajan, A., E.A. Bihn, R.B. Gravani, D.L Scott, and M.P. Pritts. (2000). Food safety begins on the farm. A grower’s guide. Good agricultural practices for fresh fruits and vegetables. Cooperative State Research, Education, and Extension Service, United States Department of Agriculture and the United States Food and Drug Administration. Retrieved from http://www.gaps.cornell.edu/FSBFEng.html

Rangarajan, A., E.A. Bihn, M.P. Pritts, and R.B. Gravani. (nd). Food safety begins on the farm. A grower self assessment of food safety risks. Cornell University, Department of Food Science and Department of Horticulture. Retrieved from http://www.gaps.cornell.edu/farmassessmentws.html

Reeve, J. and D. Drost. (2012). Yields and soil quality under transitional organic high tunnel tomatoes. HortScience 47:38-44.

Waldman, K.B., D.S Conner, J.A. Biernbaum, M.W. Hamm, and A.D. Montri. (2012). Determinants of hoophouse profitability: A case study of 12 novice Michigan farmers. HortTechnology 22: 215-223.

Waterer, D. (2003). Yields and economics of high tunnels for production of warm-season vegetable crops. HortTechnology. 13:339-343.

Waterer, D. and J. Bantle. (2000). High tunnel temperature observations. University of Saskatewan. Retrieved from http://www.usask.ca/agriculture/plantsci/vegetable/resources/veg/ht_temp.pdf

Wien, H.C. (2009). Microenvironmental variations within the high tunnel. HortScience 44:235-238.

Wien, H.C. and M.P. Pritts. (2009). Use of high tunnels in the Northeastern USA: Adaptation to cold climates. Acta Hort. 807:55-59.

Wildung, D. and P. Johnson. (2010a). Managing risk: Production comparisons between high tunnels and the field. In Nennich, T. and S. Wold-Burkness (Eds.), Minnesota high tunnel production manual for commercial growers, 2nd ed., (pp.7-12). University of Minnesota. Retrieved from http://hightunnels.cfans.umn.edu/2010Manual/Risk%20Management.pdf

Wildung, D. and P. Johnson. (2010b). Site selection. In Nennich, T. and S. Wold-Burkness (Eds.), Minnesota high tunnel production manual for commercial growers, 2nd ed., (pp.13-14). University of Minnesota. Retrieved from http://hightunnels.cfans.umn.edu/2010Manual/Structures.pdf

Wittwer, S.H. (1993). Worldwide use of plastics in horticultural production. HortTechnology 3:6-19.

Acknowledgements

This material is based upon work supported by the Natural Resources Conservation Service, U.S. Department of Agriculture, under NRCS Agreement Number 69-1218-0-28. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the authors and do not necessarily reflect the view of the U.S. Department of Agriculture.

We would like to thank Justine Rushing for her assistance with data collection.

Disclaimer

Mention of a trademark, proprietary product, or vendor does not constitute a guarantee or warranty of the product by the University of Maine and does not imply its approval to the exclusion of other products or vendors that also may be suitable.