Journal of the NACAA

ISSN 2158-9429

Volume 7, Issue 1 - May, 2014

Survey of Management Practices Used by West Virginia Farmers to Make Round Bale Silage

- Straight, A.M., Extension Agent and Extension Instructor, Ritchie County, WVU Extension Service

Shockey, W.L., Extension Agent and Extension Associate Professor, Preston County, WVU Extension Service

Rayburn, E.B., Forage Specialist and Professor, WVU Extension Service

Loyd, B.M., Extension Agent and Extension Associate Professor, Lewis County, WVU Extension Service

ABSTRACT

Plastic wrapped round bale silage (baleage) samples analyzed by WVU Extension Service faculty showed that fermentation was often not adequate to provide the necessary acidity to inhibit Clostridia bacteria growth and subsequent degradation by secondary fermentations. County-based faculty distributed surveys to determine if WV farmers who produce baleage knew, understood, and followed best management practices needed to make high quality baleage. Results indicated that educational programs should cover optimum moisture at baling, time between baling and wrapping, amount of wrap needed per bale, and inspection of stored bales.

Introduction

Plastic wrapped round bale silage (also known as baleage) is forage preserved by anaerobic fermentation of sugar into acid. To manage for good acid fermentation the forage needs to have the proper bacteria present, high sugar content that the bacteria can ferment into acid, and be sealed off from oxygen to cause anaerobic fermentation needed to produce the acids that preserve the baleage, and to prevent secondary fermentation during storage.

Based on forage analysis of plastic wrapped baleage WVU Extension Service faculty found that baleage often has not fermented adequately to develop the acidity needed to protect the forage from bacterial contamination. This can result in livestock death, including beef cattle, due to botulism poisoning (Kung, 2002; Sullivan, 2007) and we theorize this mechanism may have caused several cases of botulism in West Virginia beef cattle herds that consumed baleage, but were not exposed to traditional contamination, such as a decomposing carcass. The best management practices (BMPs) needed to make high quality baleage are reported in the agriculture research/extension literature (McCormick, 2006; Sullivan and McKinlay, 1998; Tietz, 2007; Vough and Glick, 1993). This survey was conducted to determine how well beef cattle producers in West Virginia know of, understand, and implement these BMPs that affect the fermentation in baleage.

Methods

This research used a questionnaire administered to farmers producing plastic wrapped baleage. Based on the research literature and consultation with Dr. Les Vough (professor emeritus University of Maryland) we developed the following list of BMPs that produce well-fermented baleage. These BMPs are:

- Make haylage from high quality/early growth forage (late boot to early head) since it has higher sugar content that is needed to produce good haylage fermentation.

- Mow forage without conditioning once the dew has dried so that the moisture in the haylage is within the plant and not on the surface.

- Mow forage into a wide swath for rapid and uniform wilting to 50-60% moisture for best fermentation, which takes about 4 to 6-hours.

- The forage should not be tedded since tedding leaves stems oriented at random while parallel stems will allow baling denser bales. Tedding is the process designed to increase air flow around wilting forage by disturbing the mown, wilting forage mass with a device equipped with horizontally rotating tines.

- Rake the forage into a windrow and bale in a tight dense bale to reduce air (oxygen) inside bale. Pre-cutters in the baler increase bale density and improve fermentation. Bale to a uniform bale diameter needed to exclude air where bales come together when using in-line tube wrappers. Also, bale size and weight needs to be compatible with tractor and loader capacity.

- Wrap bales in plastic within 2-hours to exclude air using at least 6 mils of plastic (8 mils better) and 50% overlap and 50-55% stretch. Wrap in dry weather for plastic to stick.

- Store bales in an area that is relatively level with no sharp stones. Stack bales to reduce sunlight exposure to save plastic and reduce sweating, north-south orientation of bales evens out sunlight on both sides of bale. Put flat, multi-layer plastic end on ground.

- Inspect stored bales weekly, repair tears and holes to prevent spoilage and secondary fermentation using tape made for plastic wrap not duct-tape.

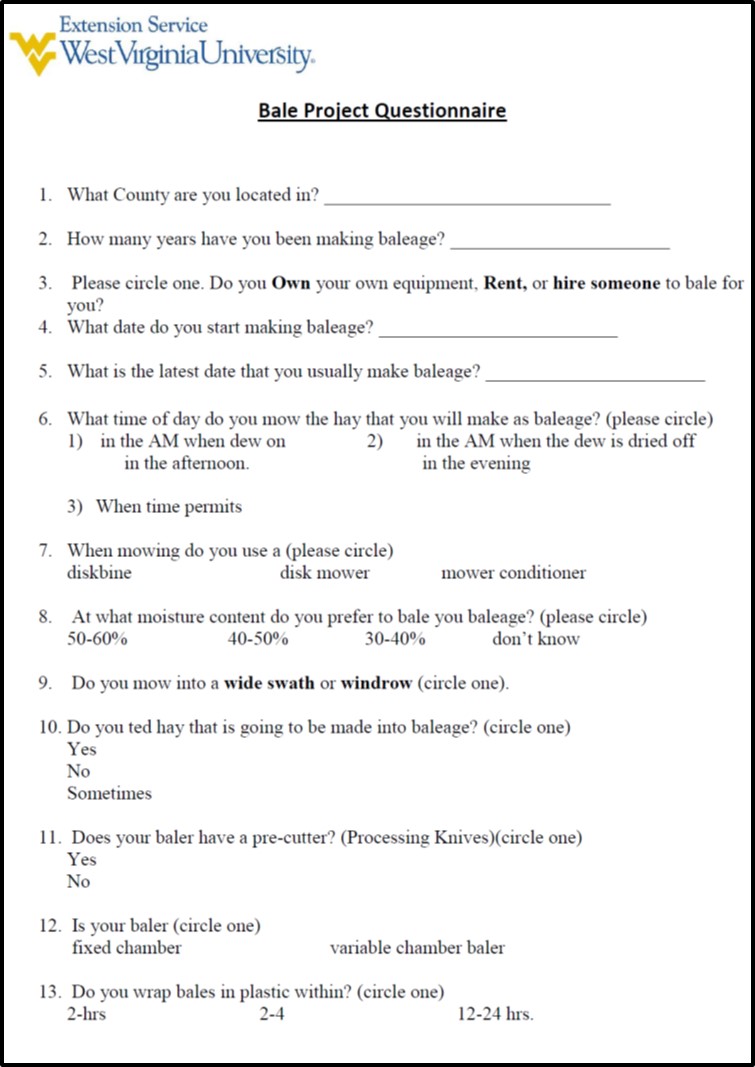

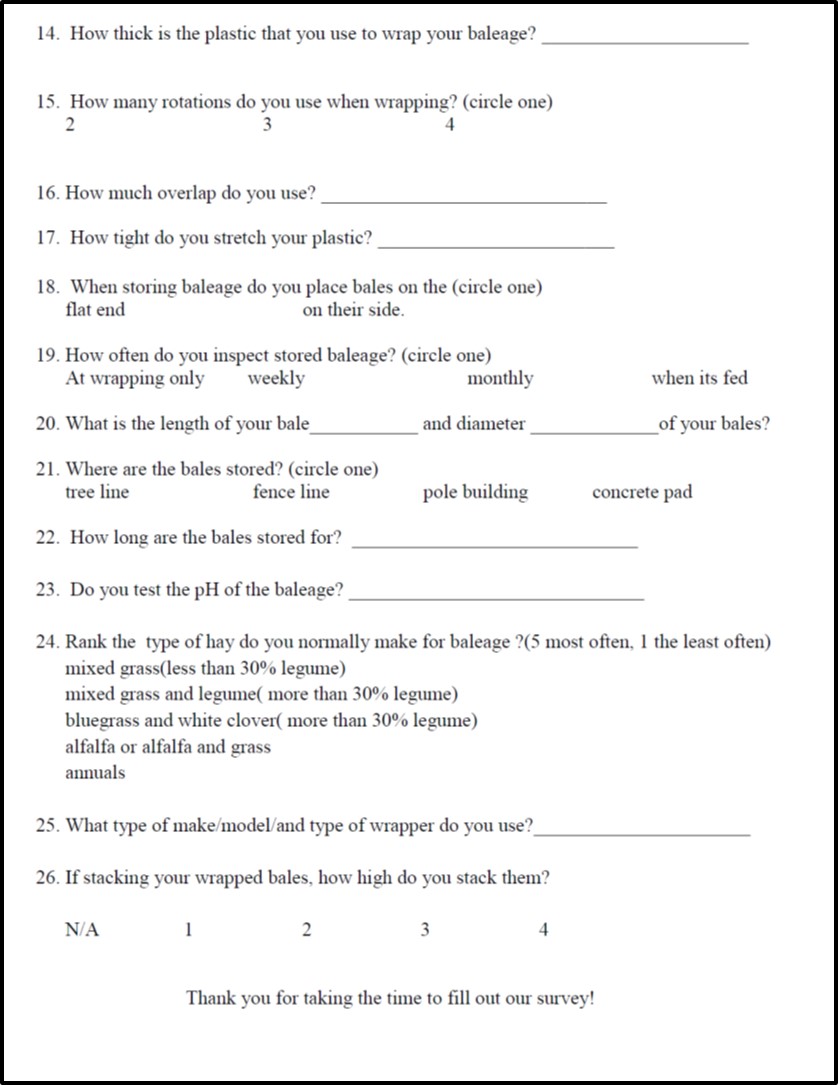

Based on these BMPs a questionnaire was developed, reviewed by team members and modified. County faculty, working with local equipment dealers, found farmers who make plastic wrapped round bale silage and who were willing to respond to the survey; the survey instrument is shown in figure 1. Survey results were summarized using general descriptive statistics (Hintze, 2013).

Figure 1. Survey instrument used to evaluate West Virginia farmers implementation of baleage BMPs.

Results and Discussion

84 farmers returned surveys from 19 counties in West Virginia. For some questions farmers gave more than one answer or left a question blank. Therefore the number of responses totaled greater than or less than the number of surveys submitted.

On average, surveyed farmers have made baleage for 11 years and 89% of the farmers own all their own equipment. Of surveyed farmers 39% made baleage from grass forage while 24% used mixed grass-legume forage, and 50% stored their baleage for 8 months.

Producer implementation of baleage BMPs were as follows:

1. Make baleage from high quality/early growth forage (late boot to early head) since it has higher sugar content that is needed to produce good baleage fermentation.

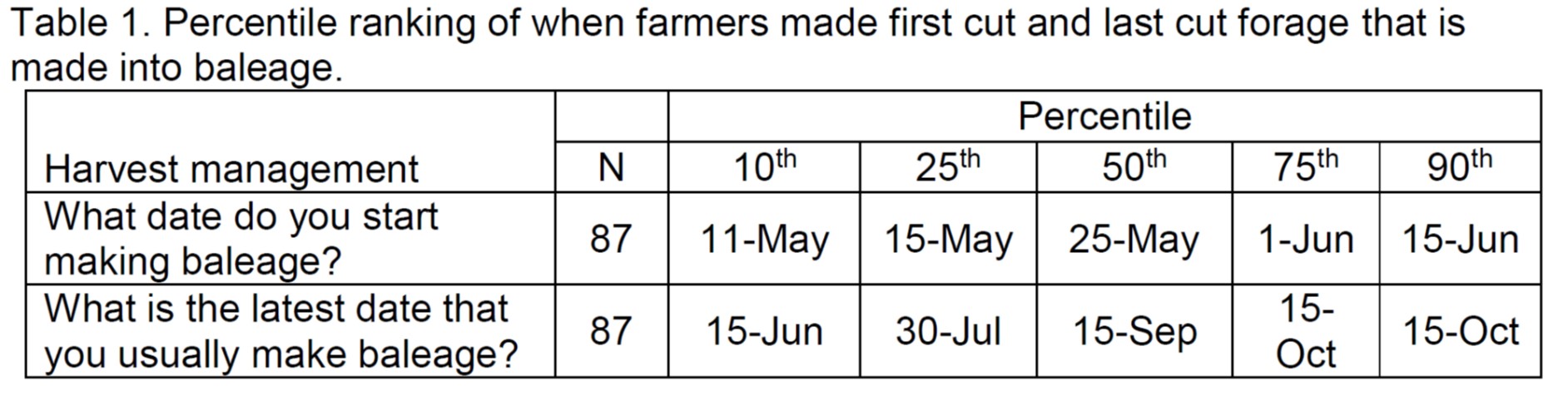

Surveyed farmers are doing a good job cutting hay at an early growth stage with 50% starting by May 25 and 75% starting by June 1 which are the approximate dates that local cool-season grasses start heading (Table 1). Aftermath baleage was made by 50% of these producers.

2. Mow forage without conditioning once the dew has dried so that the moisture in the baleage is within the plant and not on the surface.

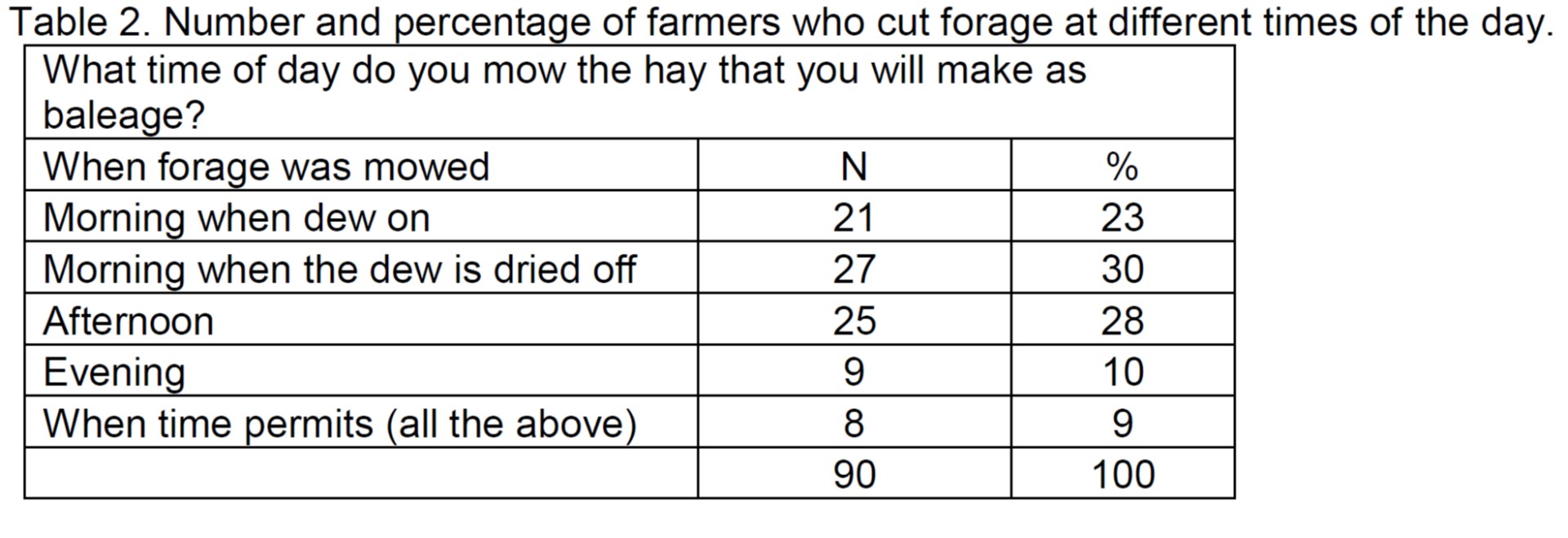

Farmers have a variety of views on when to mow their forage with 23% mowing in AM with dew on the forage, 30% in the AM with dew off, 28% in the PM, 10% in the evening, and 9% whenever they can get to it (Table 2). For good fermentation any time after the dew is off is best with afternoon and evening having the highest forage sugar content for fermentation. Over 68% of these farmers are mowing in accordance with this BMP. When mowing, 56% of the farmers mowed without conditioning while 44% used a conditioning mower.

3. Mow forage into a wide swath for rapid and uniform wilting to 50-60% moisture for best fermentation, which takes about 4 to 6-hours.

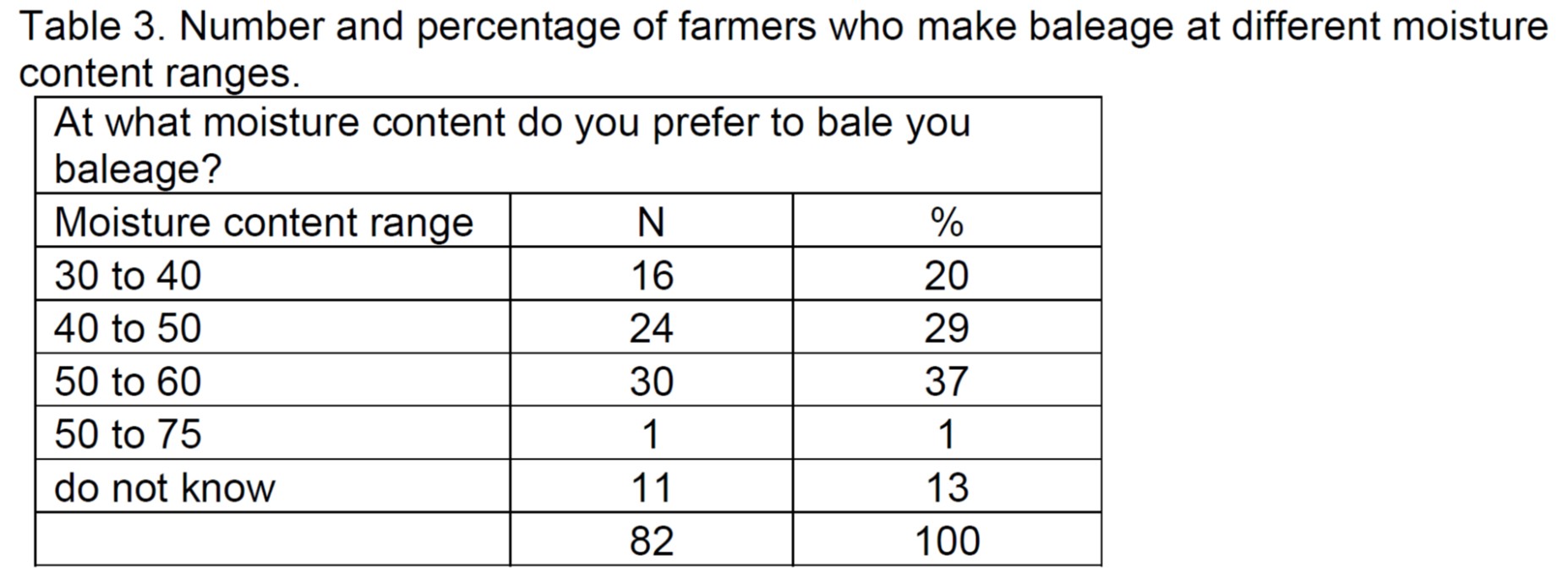

When mowing, 70% of producers mowed into a wide swath and 30% mowed into a windrow. Only 37% of producers try to bale at 50-60% moisture, with 49% baling at moisture levels drier than 50%, and 13% saying they do not know the forage moisture content at baling (Table 3).

4. The forage should not be tedded since tedding causes the stems to be placed at random orientations; when stems remain in a parallel orientation bales can be made denser.

Thirty-six percent of the surveyed farmers always tedded, while 48% did not ted, and 16% ted sometimes (Table 4).

5. Rake the forage into a windrow and bale in a tight, dense bale to reduce air (oxygen) inside bale. Variable chamber balers and pre-cutters in the baler increase bale density and improve fermentation. Bale to a uniform bale diameter needed to exclude air where bales come together. Also, bale size and weight needs to be compatible with tractor and loader capacity.

Of farmers surveyed 76 percent used variable chamber balers. Only 8% of farmers have pre-cutters on their balers.

6. Wrap bales in plastic within 2-hours to exclude air using at least 6 mils of plastic (8 mils better) using 50% overlap and 50-55% stretch. Wrap in dry weather for plastic to stick.

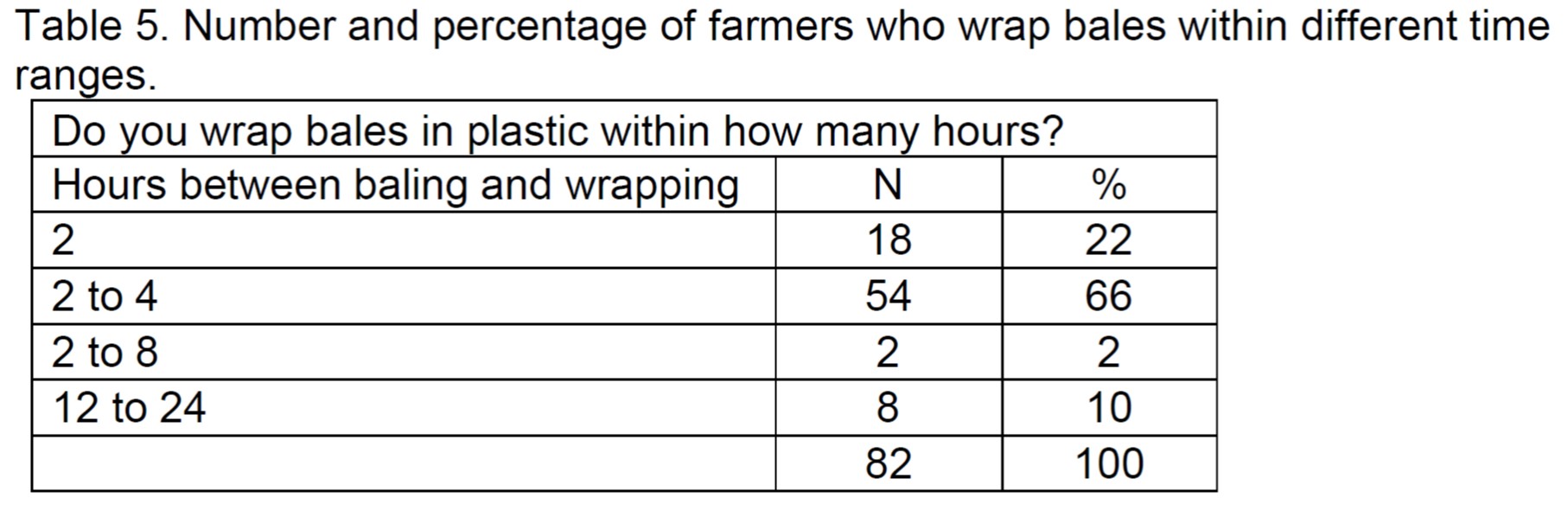

Only 22% of farmers reported wrapping baleage within 2-hours of baling with another 66% wrapping within 2- to 4-hours of baling (Table 5).

Of farmers surveyed 50% wrapped bales three times and 50% of the farmers use a 33% overlap; resulting in 50% of the farmers having 4.8 effective layers of plastic on the bale (Table 6). Most producers reported using 1 mil plastic (71%) thus the 4.8 effective layers is less than the recommended 6-8 mils. Only 31% of respondents were comfortable answering the degree of stretch being used during wrapping with the largest response (18%) being 50% stretch. Another 36% answered that it was tight and 16% answered “unknown”.

7. Store bales in an area that is relatively level with no sharp stones. Stack bales to reduce sunlight exposure to save plastic and reduce sweating, north-south orientation of bales evens out sunlight on both sides of bale. Put flat, multi-layer plastic end on ground.

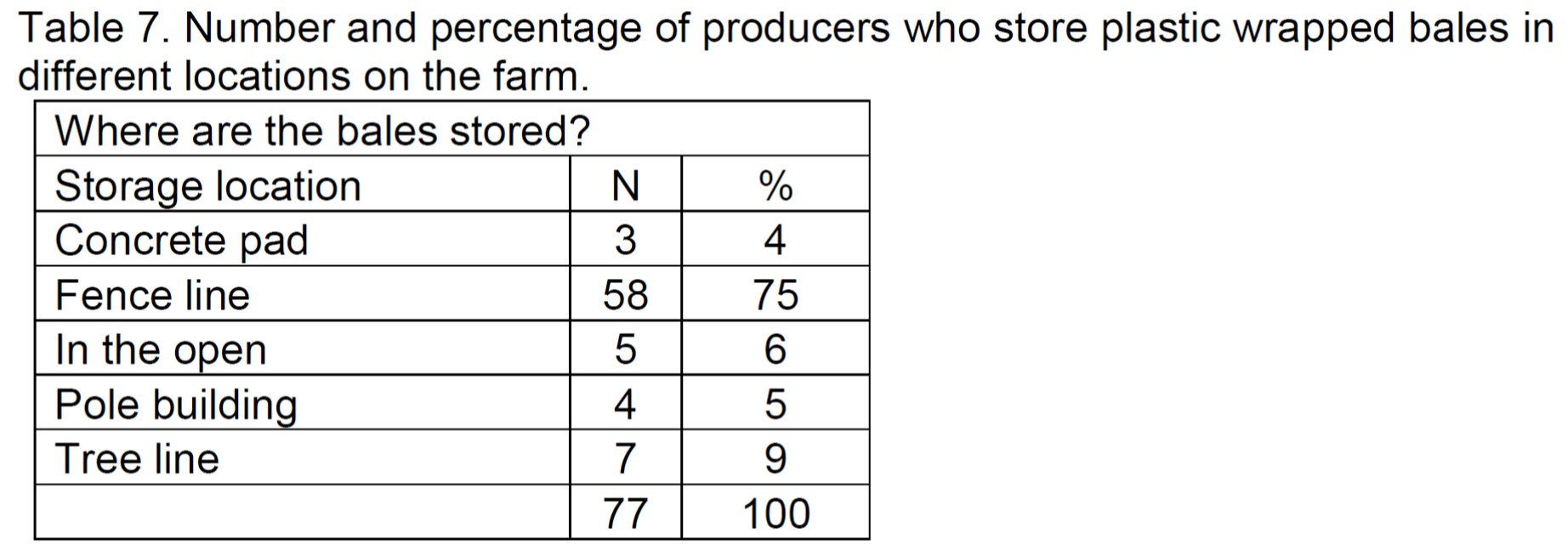

Farmers were mixed on how to set wrapped bales with 51% putting them on the bales end where the plastic is thickest and 49% putting the bales on their side. For storage 75% of farmers store bales along a fence line, 9% along a tree line and 5% in a pole barn (Table 7).

8. Inspect stored bales weekly, repair tears and holes to prevent spoilage and secondary fermentation using tape made for plastic wrap not duct-tape.

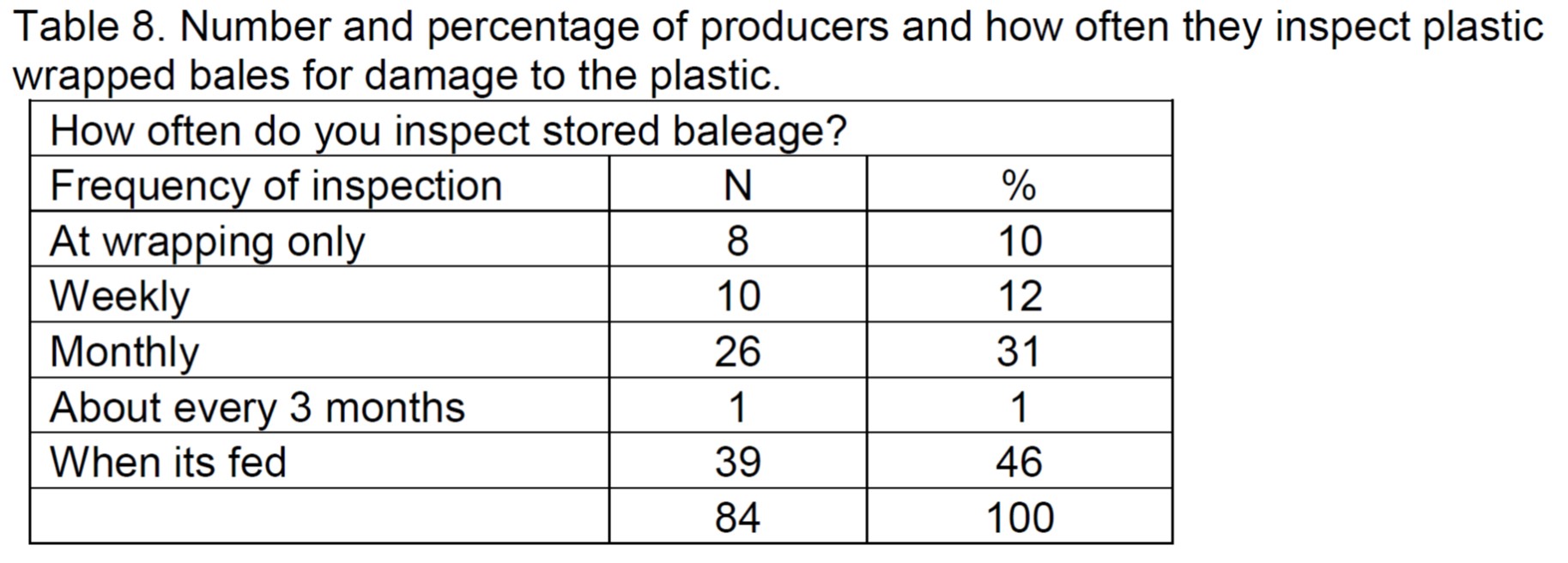

Only 12% of farmers reported inspecting bales weekly and 46% only inspect bales at feeding (Table 8).

The majority of farmers are using recommended BMPs that insure high forage quality, promote good wilting, and lead to producing dense bales. However, there are major management short falls in implementing BMPs required for good oxygen exclusion that is essential for good fermentation. Of surveyed farmers only 37% bale forage at 50-60% moisture, 22% wrap within 2-hours, and 50% used 4.8 mils or less plastic. During the storage period only 12% inspect baleage on a weekly basis for damaged plastic.

These four BMPs need to be addressed by producers to improve the quality of fermentation in their baleage and to maintain bale quality during the storage period. Forage moisture can be monitored using hand held or machine mounted electronic moisture meters. Labor and machinery management is needed to ensure that wrapping occurs within 2-hours after baling and that bales are inspected weekly. Proper monitoring and adjustment of the wrapper is needed to ensure 6 or more mils of plastic cover each bale.

We cannot extend these results to all West Virginia producers who make baleage because the survey was not administered at random and the number of respondents was relatively low. However, certain management shortfalls consistently appeared among this surveyed group and form a reasonable basis from which extension faculty can develop educational programs for farmers to improve implementation of baleage BMPs.

Conclusions

Priority topics for educational programs should include 1) optimum moisture at baling, 2) time management between baling and wrapping, 3) amount of wrap needed per bale, and 4) regular inspection of stored bales.

Acknowledgements

The following faculty and staff provided essential contributions to this study which could not have been completed without their support. J.J. Barrett, Wood County; Brandy Brabham, Roane County; Debbie Friend, Braxton County; Greg Hammons, Pocahontas County; Ronnie Helmondollar, Randolph County; Sheryl Jarvis, Monongalia County; John David Johnson, Jackson County; Jennifer Poling, Tucker County; David Richmond, Raleigh and Summers County; H.R. Scott, Monongalia County; David Seymour, Pendleton County; Brian Sparks, Nicholas County; Rodney Wallbrown, Mason County; Brian Wickline, Monroe County; and David Workman, Hardy County.

Funding for this project was provided through an Extension seed grant and the WVU Extension Service, Agricultural and Natural Resources Division.

References

Hintze, J., 2013. NCSS 9. NCSS, LLC. 329 North 1000 East, Kaysville, Utah, USA. www.ncss.com.

Kung, Jr., L. 2002. Botulism in Cattle. Delware Cooperative Extension Service on-line reference. http://ag.udel.edu/anfs/faculty/kung/documents/BotulisminCattle9-02.pdf, Accessed March 12, 2014.

McCormick, M. 2006. Bale Silage Production Issues. Proceedings of the 60th Southern Pasture and Forage Crop Improvement Conference, April 11-13, Auburn, AL. http://spfcic.tamu.edu/proceedings/2006/mcmormick.pdf. Accessed March 12, 2014.

Sullivan, P. and J. McKinlay, 1998. Maintaining Quality in Large Bale Silage. Fact Sheet. Ontario Ministry of Agriculture and Food. http://www.omafra.gov.on.ca/english/crops/facts/98-069.htm. Accessed March 12, 2014.

Sylvester, P. 2007. Botulism, Forages, and Livestock. Delaware Cooperative Extension Service on-line reference. https://extension.udel.edu/kentagextension/2007/10/12/botulism-forages-and-livestock/, Accessed March 12, 2014.

Tietz, N. 2007. Best and Worst Silage. Hay and Forage Grower. http://hayandforage.com/mag/best_worst_silage, Accessed March 12, 2014.

Vough, L. R. and I. Glick. 1993. Round Bale Silage. (In) Silage Production from Seed to Animal. Northeast Regional Agricultural Engineering Service. Ithaca, N.Y. NRAES-67. 302 p.