Journal of the NACAA

ISSN 2158-9429

Volume 8, Issue 1 - June, 2015

High Tunnel Pest Exclusion System: Laboratory and Field Experiences

- Majumdar, A. Z., Extension Specialist, Alabama Cooperative Extension System

Ann Chambliss, IPM Program Associate, Alabama Cooperative Extension System

Will Mastin, Producer, Local Appetite Growers

Steve Carpenter, Producer, Jack-o-Lantern Farms

ABSTRACT

This article provides follow-up information about a permanent pest exclusion system introduced earlier by this author (“Net House Vegetable Production”, Journal of the NACAA, 2011, Vol. 4, Issue 1). Physical exclusion of insect pests is a major integrated pest management tactic recommended by the USDA National Organic Program. In this article, we describe the use of low-cost shade cloths for a permanent modification of high tunnels (High Tunnel Pest Exclusion or 'HTPE' system). Woven shade cloths with 40-50% grades can exclude leaffooted bugs and stink bugs along with moth pests resulting in major improvement in produce quality.

Introduction

Alabama Extension Sustainable Agriculture/Small Farm IPM program has been studying pest exclusion on a commercial scale since 2011 due to increasing demand for IPM information from producers. An IPM training module on pest exclusion tactics is available for readers at http://www.aces.edu/anr/ipm/Vegetable/pestexclusion. Due to intense competition for early produce, many small and medium scale farms are heavily investing in high tunnels. NRCS Environmental Quality Incentives Program in Alabama has supported the construction of numerous high tunnels since 2010, but many new producers were lacking comprehensive training in protected agriculture systems. High tunnel producers in Alabama face major challenges from leaffooted bugs and stink bugs since those insects prefer hot growing conditions and densely planted crops. Moth pests like hornworms, loopers and fruitworms are also major threats to the mature produce. Various methods of pest exclusion have been tried in the field with different levels of success, including use of floating row covers (Saalau et al. 2011), mosquito nets (Martin et al. 2006), and 50-mesh net houses (Feng-Cheng et al., 2010; Majumdar and Powell, 2011).

A net house is a permanent sealed structure with one access point; it is designed to keep insect pests away for season-long protection. Net houses are very popular in many European, Asian, and African countries as an alternative crop production system. Although a net house can be very useful for high pest pressure regions of southern U.S. (Majumdar and Powell, 2011), the major drawbacks of a net house can be: 1. High cost of material; 2. High maintenance cost; 3. High humidity due to reduced air movement. As explained later in this article, the high tunnel pest exclusion (HTPE) system using woven shade cloths can be a low-cost pest exclusion technology with minimum side effects. The laboratory observations reported herein and net house studies completed earlier (Majumdar and Powell, 2011) provide compelling evidence about the feasibility of a permanent pest exclusion systems suitable for existing high tunnel crop producers.

Laboratory and Field Methodology

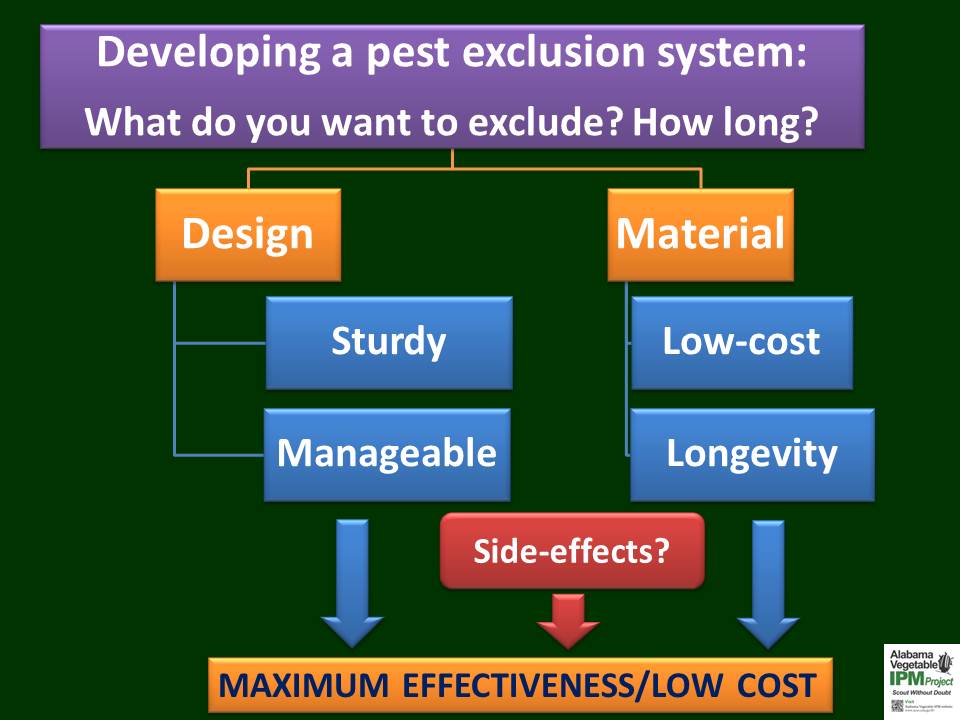

Basic principles of permanent pest exclusion systems (Figure 1): The starting point of pest exclusion systems is to decide what the target insect pests are before making an investment. The two basic aspects of HTPE system include: 1. Material: Ideally, exclusion material should be economical, easy to maintain, and replaceable. Ideal materials should also have minimum side-effects like exclusion of beneficial insects and pollinators; and. 2. Design: Ideally, design should be sturdy and manageable with adequate space for growing crops.

Figure 1. Basic aspects of high tunnel pest exclusion or HTPE system.

Construction of HTPE models for rapid laboratory tests (Figure 2): In 2014, we began developing high tunnel models (10 inch by 6 inch) with 0 (control), 30, 40, or 50% woven shade cloths supplied by Grainger (Lake Forest, IL), Green-Tek (Janesville, WI) or Poly-Tex (Castle Rock, MN). The models were housed in 15 inch x 8 inch glass display cases bought from a local craft store. The models were made by bending several pieces of metal wires; the side- and end-walls were fitted with samples of shade cloth purchased from various vendors. The shade cloths were tightly installed using zip ties over a basic wire frame and then a clear plastic was used on the top to complete the models. We ensured tight seal of the shade cloth around the models, similar to what producers have to do for a successful HTPE system.

Figure 2. High tunnel model with 40% woven shade cloth on side- and end-walls.

Behavioral studies using live insects: Various insect pests and beneficial insects were released separately inside the glass cases with HTPE models. These cases were kept at room temperature in the dark for 48 hours to study basic insect behavior patterns. Leaffooted bugs (Leptoglossus phyllopus) reared in the entomology laboratory on organic vegetable diet were used for replicated study (three replications in time). We also studied commercially-available convergent lady beetles (Hippodamia convergens) and lacewing adults (Chrysoperla spp.). Beneficial insects were bought from Arbico Organics (Oro Valley, AZ) and tested within one week of delivery. We have also conducted nonreplicated (observational) studies with cabbage looper moths, but the results have not been reported herein.

On-farm studies of HTPE system: Till date, 30 and 50% woven shade cloths have been tested by producers in Alabama as part of on-going efforts (the high tunnel with a 30% shade cloth was badly damaged by a hurricane in 2014 and we are currently repairing the unit). Another high tunnel with 40% shade cloth is under construction in southeast Alabama. Producers Will Mastin (Local Appetite Growers, Fairhope, AL) and Steve Carpenter (Jack-o-Lantern Farms, Hamilton, AL) have provided extensive observations on insect control benefits using a HTPE system. Both are experienced producers with diversified operations and use a variety of marketing techniques for their high value crops.

Will Mastin developed an easy field-installation method for woven fabric around high tunnels using wooden boards installed on side walls and at soil level (base board). A 50% shade cloth was cut to required length and installed using a staple gun over the wooden board. A flattened piece of drip tape was put over the fabric before stapling to hold the fabric strongly. End walls were partially replaced with shade cloth to improve air movement. The fabric was tightly wrapped around the metal frame of the hoop house and held in place using metal clamps as shown in Figure 3. Crops like tomato and lettuce were planted inside the modified high tunnels with several rows of the same crops outside for comparison. Will Mastin currently has five low and high tunnels fitted with HTPE system.

Figure 3. High tunnel with 50% shade cloth on side- and end-walls prior to installation of a door, Locally Grown Appetite Farms, Fairhope, AL.

Steve Carpenter installed a 30% shade cloth around his high tunnel and followed a similar installation procedure. The shade cloth was tightly extended with no sagging or loose edges. Tomatoes were planted inside and outside the high tunnels for comparison.

Both locations had doors installed on the end-walls that were kept shut when not in use to prevent accidental entry of pests.

Results

Laboratory studies: Laboratory studies with leaffooted bugs, lady beetles, and green lacewings provided preliminary evidence of insect behavior (Table 1).

Leaffooted bug adults used in the study were about 0.8 inch long. As expected, leaffooted bugs rapidly explored all high tunnel models and rapidly penetrated the ones that did not offer adequate barrier to their movement. A 30% shade cloth did not stop bug movement whereas a 40% or a 50% shade cloth were highly effective in stopping the pests from entering the HTPE models.

Convergent lady beetles (commercial supply) were about 0.3 inches long. In the absence of a prey inside the HTPE models, lady beetles showed a weak exploratory behavior. Lady beetles were able to move across a 30% or a 40% shade cloth, but 50% woven fabric excluded them completely due to the high density of material.

Green lacewings, with their large net-like wings, were completely excluded by 40% and 50% shade cloths. Lacewings had a better exploratory behavior than lady beetles in our studies, indicated by the large influx of adults in the models within 8 hours of release.

|

|

Leaffooted bugs |

|||

|

Observation times (hours after release) |

Control |

30% shade cloth |

40% shade cloth |

50% shade cloth |

|

24 hours |

53% |

40% |

0% |

0% |

|

48 hours |

60% |

46% |

0% |

0% |

|

|

Lady beetles |

|||

|

8 hours |

4.0% |

3.7% |

1.7% |

0% |

|

24 hours |

2.7% |

2.3% |

0.7% |

0% |

|

48 hours |

1.7% |

1.0% |

0% |

0% |

|

|

Green lacewings |

|||

|

8 hours |

25% |

10% |

0% |

0% |

|

24 hours |

15% |

10% |

0% |

0% |

|

48 hours |

15% |

0% |

0% |

0% |

Table 1. Movement of pest and beneficial insects in high tunnel model fitted with or without shade cloths on side- and end-walls.

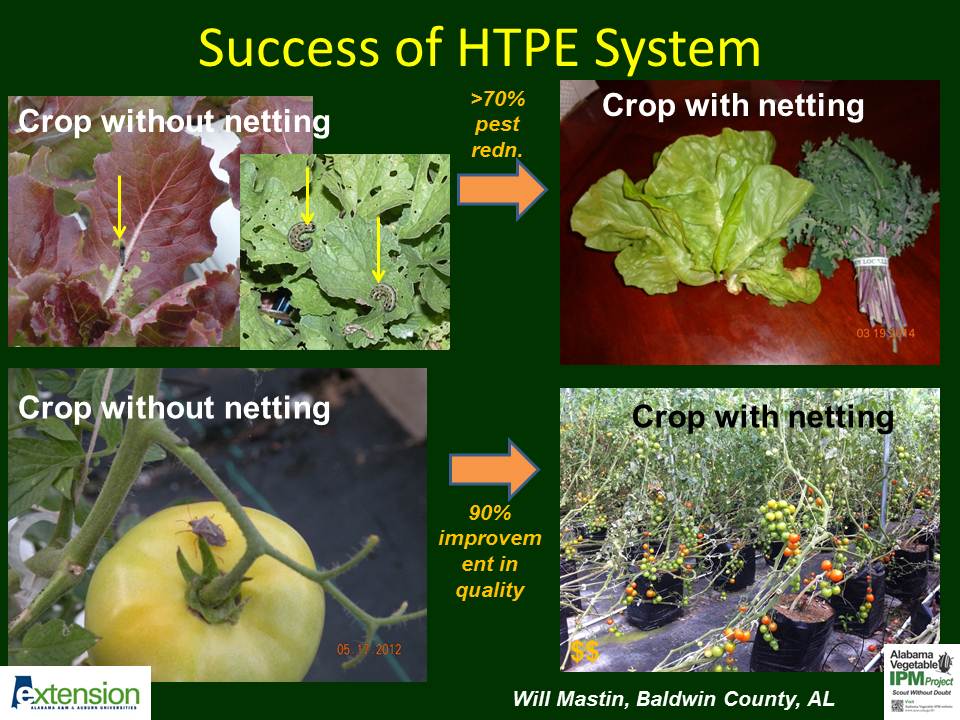

Field observations by producers: The high tunnel with a 50% shade cloth was highly effective in blocking large moths (e.g., cabbage loopers, armyworms), leaffooted bugs, cucumber beetles, and squash bugs. Timely installation of the fabric was critical to this success and results were immediate. Cherry tomatoes inside netted high tunnels had 90% reduced damage than tomatoes outside that were devastated with both leaffooted and stink bug populations. Will Mastin reported significant differences in armyworm populations; there were only three caterpillars in one tomato row inside the high tunnel with a 50% shade cloth compared to 135 caterpillars in the outside field crop for the same row length (~45 times reduction in pest pressure). He was also extremely pleased with the effectiveness of a 50% shade cloth in reducing armyworm populations on hydroponic lettuce which resulted in a major quality improvement (Figure 4). Exclusion of beneficial insects was a problem with the 50% shade cloth, similar to laboratory observations.

Figure 4. Major improvement in tomato and lettuce quality using HTPE system, Locally Grown Appetite Farms, Fairhope, AL.

Steve Carpenter had good success with the 30% shade cloth to keep out grasshoppers and moths. He also noticed the immediate cooling effect of insect netting on the side which helped the crop. According to him, this IPM tactic was the best he used to reduce moths from his high value tomatoes grown under high tunnels.

Cost effectiveness: A 40% woven shade cloth (custom-cut by Poly-Tex, Inc., MN) for covering two side-walls and one end wall of a standard NRCS high tunnel was under $420. A 30% woven shade cloth from the same supplier with similar dimensions was under $250. Although prices may vary with quality of material and supplier, it appears that modifying a high tunnel with shade cloths can be economical for the production of high value crops under high pest pressures.

Discussion

It is evident that the HTPE system can provide immediate relief to specialty crop producers in a cost-effective manner. However, the HTPE system is not a silver bullet solution to all pest problems; there are limitations to its effectiveness. For example, small insect pests like flea beetles, aphids, and white flies are able to go through the shade cloths. Total pest exclusion with a fine insect barrier has been attempted before but it favored disease development due to the trapped heat and humidity. Woven shade cloth reduced some side-effects that arise due to poor ventilation inside high tunnels without sacrificing pest management benefits.

Will Mastin has also observed that armyworms were very adaptive to insect netting. This is similar to the observations of Majumdar and Powell (2011). Female moths lay eggs on the outside of the fabric and caterpillars could crawl through the fabric to infest the crop. In 2014 production season, he resorted to using a water jet from the inside to wash off armyworm eggs and other debris to keep the shade cloth in good condition. Will Mastin now has five high tunnels with HTPE system and produces very high quality produce for direct marketing to city restaurants.

Producer observations regarding the exclusion of beneficial insects with a 50% shade cloth is supported by HTPE laboratory studies. Lady beetles were able to penetrate the 40% shade cloth but not the 50% shade cloth. Lacewings were excluded with both the 40% and 50% woven shade cloths. In other words, it appears that a 40% shade cloth can be ideal cloth for releasing lacewings inside the high tunnels (lady beetles will enter the structure naturally). Thus, adoption of the HTPE system opens the door for integrating biological control agents that otherwise may not be possinle. Use of biorational insecticides is recommended with the HTPE system as a last resort to manage the small, soft-bodied insect pests.

Producers should contact the state Extension service regarding the suitability of a HTPE system for their farm. Careful planning is required for developing site-specific IPM plans that will be economically and environmentally sustainable for small farms.

Funding

This project was funded by USDA Sustainable Agriculture Research and Education Professional Development Program (RD 309-129/5054696) and Alabama Specialty Block Grant (ADAI-PROJ 10-2014).

Acknowledgement

The Alabama Vegetable IPM Project would like to thank the producers for supporting this project and contributing to the manuscript.

Literature cited

Feng-cheng, X.U., L. Hui, L. Li-min, L.L. Fang-fang, C. Wen-hua, and L. Ding-peng (2010). Initial report about prevention and controlling of tomato leaf curl virus with 50-mesh insect nets throughout the whole growing season. China Vegetables. 8: 61-64.

Majumdar, A., and M. Powell (2011). Net house vegetable production: Pest management successes and challenges. Journal of the NACAA. Vol. 4 (1). [Online] http://www.nacaa.com/journal/index.php?jid=87

Martin, T., F. Assogba-komlan, T. Houndete, J.M. Hougard, and F. Chandre (2006). Efficacy of mosquito netting for sustainable small holder’s cabbage production in Africa. Journal of Economic Entomology. 99: 450-454.

Saalau, E., M. Gleason, and J. Batzer (2011). Can row covers stop cucurbit bacterial wilt, and are they cost effective? Horticulture and Home Pest News, Iowa State University Extension and Outreach. [Online] http://www.ipm.iastate.edu/ipm/hortnews/2011/2-9/rowcover.html

USDA National Organic Program. [Online] http://www.ams.usda.gov/AMSv1.0/nop

Additional reference materials

Pest exclustion training module, Alabama Vegetable IPM Program: http://www.aces.edu/anr/ipm/Vegetable/pestexclusion.php

Majumdar, A., and A.-M. Vazzano (2014). En macrotúnel, es importante utilizar mallas antiinsectos u otros métodos de exclusión de plagas. Productores de Hortalizas. Posted on April 16, 2014. [Online] http://www.hortalizas.com/proteccion-de-cultivos/en-macrotunel-es-importante-utilizar-mallas-antiinsectos-u-otros-metodos-de-exclusion-de-plagas/

Majumdar, A., and W. East (2014). Reducing insect pest infestations by physical exclusion. ACRES U.S.A. 44 (1): 42-43.

Majumdar, A., and M. Reeves (2013). Pest control for high tunnels. American Vegetable Grower. October 8, 2013. 61 (10): 24-25. [Online] http://www.growingproduce.com/article/36166/1/pest-control-for-high-tunnels