Journal of the NACAA

ISSN 2158-9429

Volume 8, Issue 2 - December, 2015

Hydroponic Barley Fodder Feed Tests on Replacement Rams and Ewes

- Sulser, A., Agricultural Extension Agent, Utah State University

ABSTRACT

These tests were conducted to evaluate the effect of barley fodder produced by a hydroponic system on the performance of replacement rams and ewes. In a completely block randomized test 31 replacement ewes and rams were assigned to one of the two treatments (diets) that were either control (alfalfa hay and corn/ barley grain) or fodder ( alfalfa hay, corn/barley grain, and sprouted barley). Rations were balanced in both tests and two separate tests were ran over a two year period. Each feed test lasted 100 days in length. Seed grade barely was grown in a hydroponic chamber with a growth period of 6 days. Body weight gain was not significantly different between the treatments at the (P<0.05) level. Control sheep gained 0.64 pounds per day and the sprouted barley fed sheep gained 0.54 pounds per day, collectively over the two 100 day trails. The fodder animals also consumed more dry matter on a daily basis. From an economical view, the control group had an average cost of $0.54 per head per day and the fodder group had an average cost of $0.96 per head per day. On a cost per pound of gain the control group was $0.89 per pound of gain and the fodder group was $1.71 per pound of gain. These costs showed no significant difference at the (P<0.05) level. The author understands there should be more replication, repetition, and application of treatments. These findings suggested that hydroponic fodder had no advantage over alfalfa hay and grain in replacement ewes and rams on average daily gain, while it increased the cost of the total ration.

Introduction

Asian countries have been sprouting grains for centuries to improve food value for human consumption (Resh, 2001). Hydroponics and grain sprouting for livestock started in 1699 by Woodward an English scientist (Withrow and Withrow, 1948). Bossingault a French chemist verified nutritional requirements of plants grown without soil in the mid 1800’s and Sachs and Knop worked independently to perfect hydroponic growing techniques in England in the 1860’s (Hoagland and Amon, 1938). About this time European farmers began sprouting grains for dairy cattle feed during winter months. In the 1920 and 1930’s Dr. Gericke further developed ways to grow plants on a large scale in nutrient solutions. (Butler and Oebker, 1962). Since then many companies have manufactured units to grow hydroponic sprouted grains in both large and small quantities. Systems are available to purchase in almost every country of the world. Development of these systems has enabled the fresh production of forages from barley, oats, wheat, and other grains (Rodriguez-Muela et al., 2004).

Hydroponic green fodder is produced from forage grains, having high germination rates and grown for short periods of time in specialized chambers that control the appropriate growing conditions (Sneath and McIntosh, 2003). Germination and sprouting activates enzymes that change starch, proteins, and lipids of the grains into simpler forms, example starch changes to sugars. Arguments about the suitability of green fodder in a hydroponic system as livestock feed exist on both sides (Rajendra et al., 1998: Tudor et al., 2003) Depending on the type of grain, the forge grown in a system reaches a height of 6 to 8 inches with a wet weight of 15 to 19 pounds per mat of green fodder from 2 to 2 ½ pounds of dry grain (figure 1). The length of time required to produce this mat is generally 6 to 8 days with the fodder mat made up of germinated seeds, interwoven white roots, and the green shoots (Pandey et al., 1991). The entire mat is then fed to animals and the growing space replanted to germinate a new set of seeds (Mukhopad, 1994). Limited research has been conducted to determine the cost and feeding value of hydroponic barley fodder (Thomas and Reddy, 1962; Peer and Lesson, 1985).This study was designed to assess the costs of feeding hydroponically sprouted barley and compare the average daily gain of replacement rams and ewes offered hydroponically sprouted barley.

Figure 1. Six day harvested fodder biscuit ready to be fed; shoots, roots, and seeds.

Materials and Methods

A pre-manufactured steel hydroponic growing chamber measuring 9.8 ft x 5.7 ft x 8.5 ft equipped with automatic overheard sprinklers and heating/air conditioning apparatus with a capacity of 63 polyethylene trays was used for fodder production (figure 2). Temperatures inside were controlled from 68⁰F to 70⁰F with relative humidity levels adjusted to about 70%. Fluorescent lighting was attached to one end wall supplying 12 hours of light per day. Seed grade barley was used for sprouting at the rate of 2 ½ pounds per polyethylene tray measuring 12” x 28”. The only ingredient added was water misted on barley seeds for one minute every four hours. One sixth of the trays were planted every day (9 trays per day, 22.5 pounds barley) and harvested after six days from the starting point. A six day cycle was required to supply continuous daily fodder biscuits. Nine biscuits of fodder were harvested from the growing chamber daily. It was estimated that ninety five percent of all seed germinated. After weighing the fodder, biscuits were fed in fence line feeders, whole (germinated seeds, roots, and green shoots, (figure 3).

Figure 2. Fodder Machine, 9.8 ft. long X 5.7 ft. wide X 8.5 ft. tall, fully automatic growing chamber.

Figure 3. Fodder biscuits in fence line feeders to replacement ewes in test #1.

Test #1

Twenty purebred, ten months of age replacement rams and ewes with an initial average body weight of 197 pounds for rams and 162 pounds for ewes were chosen for the test. After a two week adaptation period, the animals were assigned randomly to a control pen or an experimental pen, 6 rams in each pen and 4 ewes in each pen for a total of 4 pens. Pens were open loafing type shed with a southern exposure with approximately 120 square feet, bedded with barley straw. All groups provided with salt blocks, shared water tanks, similar feeders, and fed twice daily. All groups were wormed with dexomax at beginning of the test and shorn on the same day. Rams and ewes weighed every ten days in the afternoons before the evening feed schedule. Rations were balanced using the Montana State University Sheep Ration Balancer before the feed test began and balanced for Total Digestible Nutrients (TDN) (see table 1). All feeds were tested on a 100% dry matter basis by the Utah Department of Agriculture and Food at their Ogden, Utah lab. The names of the feed were associated with the farm it came from. This feeding test lasted for 100 days from February 1 to May 12, 2014.

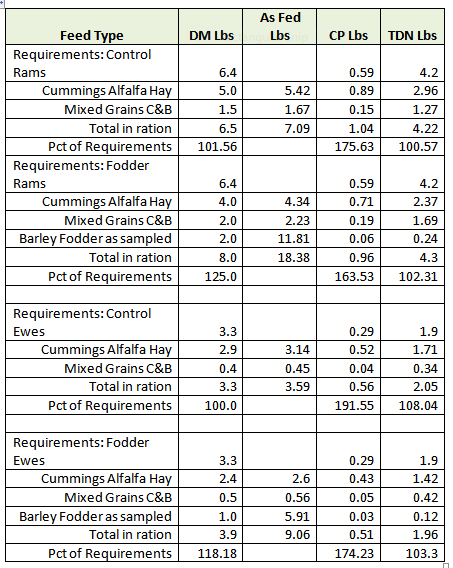

Table 1. Rations fed in test #1, balancing for TDN on a dry matter basis. Pounds fed on wet basis in column 2, TDN in column 4.

Test #2

Eleven purebred replacement rams with an average initial body weight of 124 pounds and 8 months old were chosen for this test. All were given a two week adaptation period. 6 rams were randomly assigned to the experimental pen and 5 rams randomly assigned to the control per. All protocols were exactly the same as test #1 rations balanced for TDN, (see table 2). The feeding test lasted 100 days from October 11, 2014 to January 19, 2015. The second test was ran to duplicate the first test and retest the hypothesis.

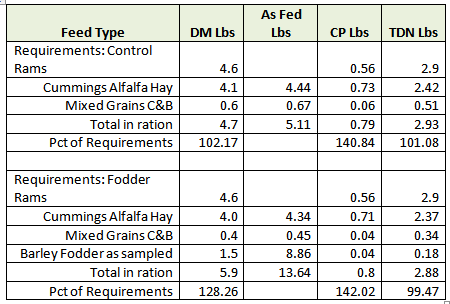

Table 2. Rations Fed in test #2, balancing for TDN on a dry matter basis. Pounds fed on wet basis in column 2 and TDN in column 4.

Results

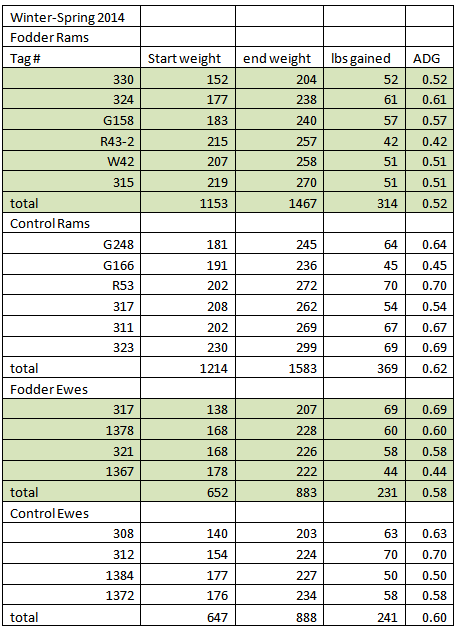

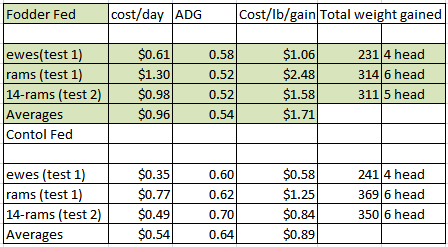

The final average live weight for the rams eating fodder was 244 pounds with a starting weight of 192 pounds and an average daily gain (ADG) of 0.52 pounds. The final average live weight of the control rams was 263 pounds with a starting weight of 202 pounds and an ADG of 0.62 pounds. Fodder ewes had an average final weight of 220 pounds with a starting weight of 163 pounds and an ADG of 0.52 pounds. Control ewes average final weight was 222 pounds with starting weight of 161 pounds and an ADG of 0.60 pounds. Data for individuals in the feeding test is shown in (table 3). Those rams eating fodder had fixed costs of $1.30/head/day with a cost per pound of gain of $2.48. Fodder ewes had fixed costs of $0.61/head/day with a cost per pound of gain of $1.06. Control rams fixed cost were $0.77/head/day and cost per pound of gain was $1.25. Control ewes had fixed costs of $0.35/head/day and cost of pound of gain was $0.58. See (table 5) below for data.

Table 3. Starting and ending weights for replacements in test #1, including ADG in column 5.

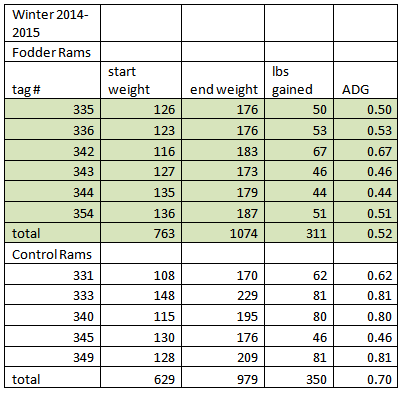

Test 2 rams eating fodder had starting weights averaging 127 pounds and had finishing average weights of 179 pounds with an ADG of 0.52 pounds. Test 2 control rams average starting weight was 125 pounds with average finished weights of 195 pounds and ADG of 0.70 pounds. Data for individuals in the feeding test are shown in (table 4). Rams eating fodder had fixed costs of $0.98/head/day with a cost per pound of gain of $1.58. Rams on the control diet had fixed costs of $0.49/head/day with a cost per pound of gain of $0.84. See (table 5) below for individual data.

Table 4. Starting and ending weights for test #2 including ADG in column 5.

Table 5. Cost per pound of gain for each group for tests #1 and #2. The average for the fodder group is $1.71 and the average for the control group is $0.89. (It should be noted that adding in all costs would increase cost per day to $1.01 and cost per pound of gain to $1.87 for fodder groups).

Conclusions

Body weight gain was not significantly different between the treatments at the (P<0.05) level. Control sheep gained 0.64 pounds per day and the sprouted barley fed sheep gained 0.54 pounds per day, collectively over the two 100 day trails. The fodder animals also consumed more dry matter on a daily basis. From an economical view the control group had an average cost of $0.54 per head per day and the fodder group had an average cost of $0.96 per head per day. These costs did not include additional labor (15 minutes per day), water (15-18 gallon per day), power ( $2.00 per day, manufacturer estimate), and purchase price of growing machine ($9,500). Including those costs would increase the fodder $7.10 per day or $0.0525 per pound per day, which would increase the totals in (table #5) to $1.01 cost per day and to $1.87 cost per pound of gain: (labor .025 hour @ $10.00 per hour, power $2.00 per day, machine cost $2.60 per day($9,500/10 years/365days)). On a cost per pound of gain the average for the control group was $0.89 per pound of gain and the average for the fodder group was $1.71 per pound of gain. These costs showed no significant difference at the (P<0.05) level. These findings suggested that hydroponic fodder had no advantage over alfalfa hay and grain in replacement ewes and rams on average daily gain, while it increased the cost of the total ration. The author understands that these feeding experiments were not scientific. Further, the author understands there should be more replication, repetition, and application of treatments. More research needs to be completed on hydroponic sprouted barley feed on these and different species of animals.

References

Resh, H.M., (2001). Hydroponic Food Production, 6th ed., 567 pp.,Woodbridge Press,Santa Barbara,CA.

Rodriguez-Mulea, C., Rodriguez, H. E., Ruiz, O., Flores, A., Grado, J. A. and Arzola, C. (2004). Use of Green Fodder Produced in Hydroponic System as Supplement for Lactating Cows During the Dry Season. Proceeding of American Society of Animal Science, 56: 271-274. (Western Section)

Rajendra, P., Seghal, J. P., Patnayak, B. C. and Beniwal, R. K. (1998). Utilization of Artificially Grown Barley Fodder by Sheep. Indian J. Small Rumin., 4(2): 63-68.

Mukhopad, Yu. (1994). Cultivating Green Forage and Vegetables in the Buryat Republic. Mezhdunarodnyi Sel'skokhozyaistvennyi Zhurnal, 6(1): 51-52.

Thomas, J. W. and Reddy, B. S. 1962. Sprouted Oats as a Feed for Dairy Cows. Quarterly Bulletin of the Michigan Agricultural Experiment Station, 44(2): 654-655.

Peer, D. J. and Lesson, S. (1985a). Feeding Value of Hydroponically Sprouted Barley for Poultry and Pigs. Anim. Feed Sci. Technol., 13(3-4): 183-190.

Pandey, H.N. and N.N. Pathak, (1991). Nutritional evaluation of artificially grown barley fodder in lactating crossbred cows. Indian Journal of Animal Nutrition, 8(1): 77-78

Sneath, R. and F. McIntosh, 2003. Review of hydroponic fodder production for beef cattle. Department of Primary Industries: Queensland Australia 84. McKeehen, pp: 54.

Withrow, R.B., and Withrow, A.P. (1948). Nutri-culture. Lafayette, Indiana, Agricultural Experiment Station, Purdue University.

Hoagland, D.R., and Arnon, D.I. (1938). The water-culture method for growing plants without soil. Berkeley, California, California Agricultural Experiment Station, The College of Agriculture.

Butler, J. D., and Oebker, N.F. (1962). Hydroponics as a hobby. Urbana, Illinois, University of Illinois, College of Agriculture, Extension Service in Agriculture and Home Economics.

Tudor, G., Darcy, T., Smith, P., and Shallcross, F. (2003). The intake and liveweight change of droughtmaster steers fed hydroponically grown, young sprouted barley fodder (Autograss), Department of Agriculture Western Australia.