Journal of the NACAA

ISSN 2158-9429

Volume 9, Issue 2 - December, 2016

Production Potential of Teff Grass as a Forage Crop in Mississippi

- Lemus, R. , Extension Forage Specialist, Mississippi State University Extension Service

White, J.A., Forage Variety Testing Manager, Mississippi State University

ABSTRACT

Teff grass (Eragrostis tef) is a relatively new warm-season summer annual grass that is gaining popularity as a forage crop for livestock producers and hay producers in the southern USA. Two studies were conducted from 2010 to 2011 and in 2014 with the objective of evaluating forage yield and quality of teff grass depending on the fertility regime, establishment method, harvest maturity and cutting height. Both studies were conducted at the Henry H. Leveck Animal Research Farm on the campus of Mississippi State University in a Stough fine sandy loam soil. Study #1 was a 3 x 6 factorial in a randomized complete block design with all treatments replicated three times. Three cultivars were used in the study in 2010: ‘Tiffany’ teff grass, ‘Red River’ crabgrass and ‘Quick-N-Big’crabgrass. In 2011, the teff grass cultivar ‘Dessie’ was added to the study. Six nitrogen treatments were applied to each cultivar. Nitrogen treatments consisted of 0, 30, 60, and 90 lb N/ac as single application or split applications using urea ammonium sulfate (33-0-0). The 60 lb N/ac rate was split in 30 lb/ac applications while the 90 lb N/ac was split in 45 lb/ac applications when plants achieved three inches of growth after planting and after the first harvest. There was a significant N treatment interaction (P<0.0031) and cultivar interaction (P<0.0010) in 2010 growing season for seasonal biomass yields. No significant differences in biomass production were observed in 2011 for the N treatments (P<0.2757) or the cultivars (P<0.3452). In 2010, there was a significant N application rate effect for CP (P<0.0155) and a significant cultivar interaction for NDF (P<0.0078) and FRUC (P<0.0263). Study #2 was a 2x3x2 factorial in a split-split plot arrangement replicated three times. The main plots were the planting methods (broadcast and drilled), the subplots were the three growth stages [vegetative (10 inches of growth), boot stage (when the developing seed head begins to push through the uppermost leaf sheath), and seed head (seed heads were completely visible)] and the sub-subplots were the two cutting stubble heights (3 and 5 inches). There was no significant differences between the establishment methods or growth stages. However, drilling the seed produced 12% greater yield than the broadcast method.

Abbreviations: N, nitrogen; P, phosphorus; K, potassium; CP, crude protein; ADF, acid detergent fiber; NDF, neutral detergent fiber; FRUC, fructan; WSC, water soluble carbohydrates; CV, coefficient of variation; LSD, least significant difference.

Keywords: Teff grass, crabgrass, warm-season annual grass, forage quality, vegetative stage, cutting height, establishment.

INTRODUCTION

Teff grass (Eragrostis tef) is a relative new warm-season summer annual grass that is gaining popularity as a forage crop for livestock producers and hay producers in the USA, but there is limited information describing performance in Mississippi and the southern USA. This grass is native to Africa (Ethiopia) and breeding efforts have created an opportunity for new cultivars to serve as an alternative forage crop in the USA (Stallknecht, 1997). Due to its fast growing, high biomass production and competitiveness, it could be used as hay, silage, or pasture for cattle and horses (Miller, 2011).

Teff grass can be planted in late spring (mid-May to early June) in Mississippi when the soil temperature is above 70 ºF producing yields averaging more than 3,000 lb DM/ac (White et al., 2011; White et al., 2013). Teff grass yields typically range from 4 to 6 tons/ac (Norberg et al., 2009) in other parts of the USA depending on location, length of growing season, cutting schedule, as well as irrigation and fertilizer inputs. In the Mississippi forage variety trials, teff grass has only allowed for two cuts during the growing season with proper fertilization. Yields for teff grass were 18% greater than those compared to crabgrass (2,707 lb DM/ac) (Digitaria sanguinalis) in the Mississippi State University forage variety trials (White et al., 2011). Although the literature indicates that teff grass can offer good forage quality (CP 9-14%, ADF 32-38%, NDF 53-65, and TDN 55-64%) (Miller, 2011), forage quality was similar to crabgrass when harvested at the same growth stage (White et al., 2013).

Ideal environmental conditions for teff grass in its native habitat include a seasonal rainfall of 17 to 22 inches with temperatures ranging from 60 to 85 ºF (Roseberg et al., 2006). Roseberg et al. (2006) also indicated that teff is day length sensitive with reduced flowering and seed formation under short days (≤8-hr daylight) and long day (≥16-hr daylight). The recommended agronomic practices for establishing teff grass include a seeding rate of 3 to 4 lbs/ac of raw seed (6 to 8 lbs if coated seed) and seeding depth of 1/8 to 1/4 inch (Miller, 2011). Shallow planting by broadcasting the seed and cultipacking is recommended because the seed is very small and one pound of seed can contain up to 1.3 million seeds (Miller, 2011). Despite of the recommendations for grazing, teff grass has a very shallow root system and plants can be easily pulled from the ground (Johnson, 2007) causing stand loss if not managed properly. It should not be grazed or cut below a 3 to 4 inches stubble height (Eckhoff, et al., 1993). The first cut is recommended at 40 to 50 days after establishment at the boot stage and subsequent cuts approximately every 30 days (Roseberg et al., 2006).

Nitrogen and phosphorus are key limiting nutrients in teff grass production. Seasonal N application for teff grass should range from 50 to 120 lb N/ac, but most sources agree that about 30 to 50 lb N/ac at planting and in between cuttings should be sufficient (Marsalis and Lauriault, 2015). Marsalis and Lauriault (2015) also indicated that little yield advantage has been observed with nitrogen applications greater than 50 lb N/ac per cutting. In a study conducted by Holman et al. (2015) with six N rates (0, 25, 50, 75, 100, and 125 lb of N/ac) and two N Sources (urea and ESN), there was no yield response to increasing N rate. However, they indicated that urea produced 500 lb DM/ac greater than ESN. Marsalis and Lauriault (2015) studied the impact of N rate applied at 30, 60, and 90 lb N/ac as single application or in split application of 30 lb N/ac at planting and after each cutting. They indicated that there was no seasonal yield improvement with the 30 lb N/ac split application over the single application. However, teff grass yield was improved with N applications of 30 lb/ac after each cutting. They also indicated that to produce 1 ton of dry matter forage per acre approximately 25 to 30 lb of N might be required.

As previously indicated, climate is the primary determinant of the performance of teff grass based on temperature and rainfall. Understanding agronomic management practices that can increase forage production could dictate the economic feasibility of teff as a forage crop in Mississippi. Two studies were conducted from 2010 to 2011 and 2014 with the objectives of evaluating forage yield and quality of teff grass depending on the fertility regime, establishment method, harvest maturity and cutting height.

MATERIALS AND METHODS

Study #1: Evaluation of Teff Grass and Crabgrass Cultivars under Mississippi Conditions

The study was conducted during the summer of 2010 and 2011 at the Henry H, Leveck Animal Research Farm on the campus of Mississippi State University (33º 25’ 20” N, 88º 47’, 31” W). The soil type was a Stough fine sandy loam (Coarse-loamy, siliceous, semiactive, thermic Fragiaquic Paleudults). The experimental design was a 3 x 6 factorial in a randomized complete block design with all treatments replicated three times. Three cultivars were used in the study in 2010: ‘Tiffany’ teff grass, ‘Red River’ crabgrass and ‘Quick-N-Big’ crabgrass. In 2011, the teff grass cultivar ‘Dessie’ was added to the study. Six nitrogen treatments were applied to each cultivar. Nitrogen treatments consisted of 0, 30, 60, and 90 lb N/ac as single application or split applications using urea ammonium sulfate (33-0-0). The 60 lb N/ac rate was split in 30 lb/ac while the 90 lb N/ac was split in 45 lb/ac applications at establishment when plants were three inches tall and after the first harvest. Lime, P and K were applied according to soil test recommendations. Plots of teff and crabgrass were established at a seeding rate of 10 lb/ac using an Almaco plot cone planter (Almaco, Nevada, IA). Plots were established on June 8, 2010 and June 10, 2011. There were two harvest dates in 2010 (July 19 and August 26) and one harvest date in 2011 (July 23). Plots were harvested at a 3-inch stubble height when at least 50% of the plots reached a height of 8 to 12 inches. Plots were harvested using a sensation mower, removing a 42-inch swath from the center of the plot, to minimize border effect. Subsamples were collected for dry matter determination and dried in a forced-air oven at 131 ˚F until the weight remained constant. Samples collected in 2011 were ground to pass 1-mm screen using a Wiley mill (Thomas Scientific, Swedesboro, NJ) and analyzed for Crude Protein (CP), Neutral Detergent Fiber (NDF), Acid Detergent Fiber (ADF), Fructan (FRUC), and Water Soluble Carbohydrates (WSC) concentration using a Foss 6500-C Near Infra-red Reflectance Spectroscopy (NIRS) instrument (Foss North America, Eden Prairie, MN) and applying the hay equation developed by the NIRS Forage and Feed Testing Consortium (Hillsboro, WI).

Study #2: Impact of Establishment Method, Growth Stage and Cutting Height in Teff Grass Biomass Production

The study was conducted during the summer of 2014 at the Henry H. Leveck Animal Research Farm on the campus of Mississippi State University (33°25’20” N, 88°47’31” W) in a Stough fine sandy loam soil (Coarse-loamy, siliceous, semiactive, thermic Fragiaquic Paleudults). The experimental design was a 2x3x2 factorial in a split-split plot arrangement replicated three times. The main plots were the planting methods (broadcast and drilled), the subplots were the three growth stages [vegetative (10 inches of growth), boot stage (when the developing seed head begins to push through the uppermost leaf sheath), and seed head (seed heads were completely visible)] and the sub-subplots were the two cutting stubble heights (3 and 5 inches). The boot and seed head stage plots were harvested when plots reached approximately 90% of the desired growth stage. Plots were 6 ft x 10 ft and Eragrostis tef (‘Tiffany’ teff) were planted in May 22, 2014 at a rate of 10 lb PLS/ac. All plots were planted using an Almaco plot cone planter (Almaco, Nevada, IA), but when simulating the broadcast planting, all tubes were removed from the coulters to deposit the seed directly on the soil surface. Plots were fertilized with 50 lbs N/ac at three inches after emergence using urea ammonium sulfate (33-0-0) and at three days after each subsequent harvest. Lime, P and K were applied according to soil test recommendations. A 52-inch swatch was removed from the center of the plot using a commercial Ferris Z-turn mower (Munnsville, NY) equipped with a bagging system and a forage subsample was collected for dry matter determination. Subsamples were collected for dry matter determination and dried in a forced-air oven at 131 ˚F until the weight remained constant. Depending on the growth stage, plots were harvest on July 1, July 11, July 22, August 7 and August 30.

Statistical Analysis

Data were analyzed by using the General Linear Model of SAS (SAS Enterprise 9.4, 2016) and mean separation was done using the least significant difference (LSD) at α = 0.05. Data for study #1 were presented by year due to the number different harvest regimes and cultivars present.

RESULTS AND DISCUSSION

Study #1: Evaluation of Teff grass and crabgrass cultivars under Mississippi Conditions

Biomass Yield

Precipitation and average temperature were below normal for the duration study (Table 1). Precipitation was 6 and 8 inches below normal in 2011 and 2012, respectively, while temperatures were 6 and 9 ºF below normal for this time of the growing season. There was a significant N treatment interaction (P<0.0031; Table 2) and cultivar interaction (P<0.0010; Table 3) in the 2010 growing season for seasonal biomass yields. There was no N x cultivar interaction (P<0.0601). The significance for the N interaction was split in two main groups with the 60 lb N/ac as single or split application being the divide line. No significant difference was observed among the 60-single, 90-single and the 90-split N applications. On the other hand, no significant differences were observed among the control, 30-single and 60-split N applications. There was no yield differences among the two crabgrass cultivars. Despite no differences among the crabgrass cultivars, ‘Tiffany’ teff grass had 12 and 15% yield increase when compared to ‘Red River’ and ‘Quick-N-Big’.

No significant differences in biomass production were observed in 2011 for the N treatments (P<0.2757; Table 2), the cultivars (P<0.3452; Table 3) or the N x cultivar interaction (P<0.4556). Despite the lack of significant differences among N treatments, yield can be stratified into three major groups. The upper group with higher biomass yields were represented by the 60 single and 90 split N applications. The middle group was represented by the 30 single and 60 split N application. Finally, the lower group was represented by the 0 and 90 single N application. The upper and middle groups had an 18 and 12% greater yield compared to the lower biomass group. The two teff grass cultivars had greater biomass yields compared to the crabgrass cultivars. Average yield difference between teff grass and crabgrass was 10%. ‘Tiffany’ teff grass was the highest yielding cultivar in the study, similar to numbers reported by White et al. (2011).

Forage Quality

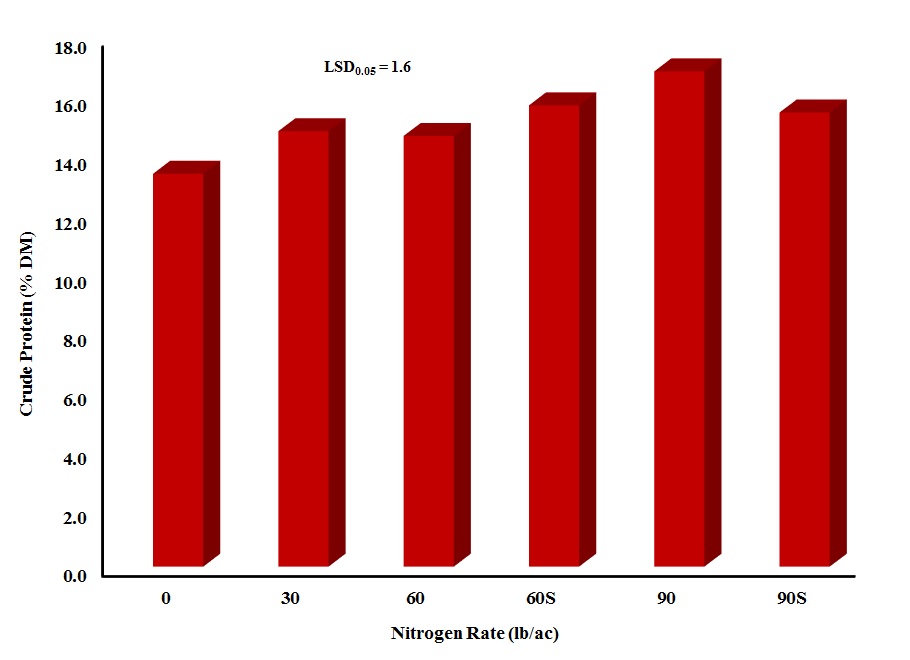

Forage quality was analyzed among the two harvests in 2010. There was a significant N application rate effect for CP (P<0.0155; Fig. 1). Differences were observed among the single rates of 0, 30, 60 N when compared to the 90 N single rate. The 60 and 90 N split rates were only significantly different from the control. Crude protein concentration among rates range from 13.4% at the control to 16.9% at the 90 N single rate. There was a significant cultivar interaction for NDF (P<0.0078) and FRUC (P<0.0263). ‘Tiffany’ teff grass had 4 and 6% higher NDF concentration than ‘Quick-N-Big’ and ‘Red River’ crabgrass, respectively. Differences in FRUC concentrations were only observed among “Tiffany’ teff grass and ‘Red River’ crabgrass, but the differences from the nutrition point of view were very small.

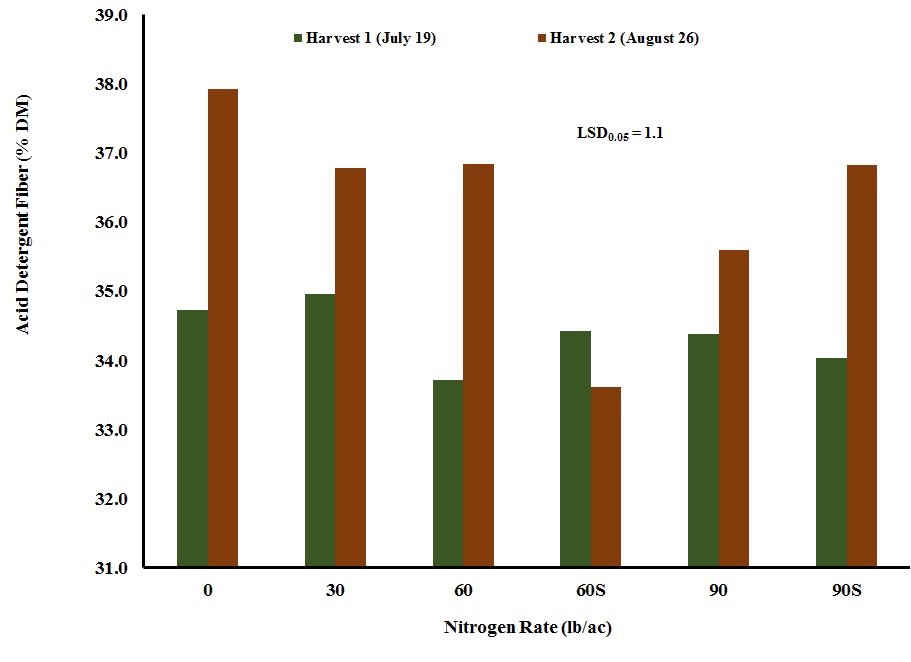

An N application rate x harvest date effect was observed for ADF concentrations (P<0.0334) (Fig, 2). Lower ADF concentrations were observed during the first harvest (Jul 19) compared to the second harvest (Aug 23) within each cultivar. There were significant cultivar x harvest date for ADF (P<0.0037), NDF (P<0.0428) and WSC (P<0.0161) (Table 4). Significant differences in ADF, NDF, and WSC were observed among cultivars during the first harvest (July 19) and not during the second harvest. During the first harvest, ‘Quick-N-Big’ showed higher ADF than the other cultivars. Concentrations of NDF and WSC were different among all three cultivars with ‘Tiffany’ teff grass having higher concentrations. Differences among dates within a cultivar were observed for ADF, NDF, and WSC. Acid detergent and NDF concentrations increase with harvest date, while WSC increased for ‘Quick-N-Big’ crabgrass during the second harvest and decreased for ‘Tifanni’ teff grass.

Study #2: Impact of Establishment Method, Growth Stage and Cutting Height in Teff grass biomass Production

Biomass Yield

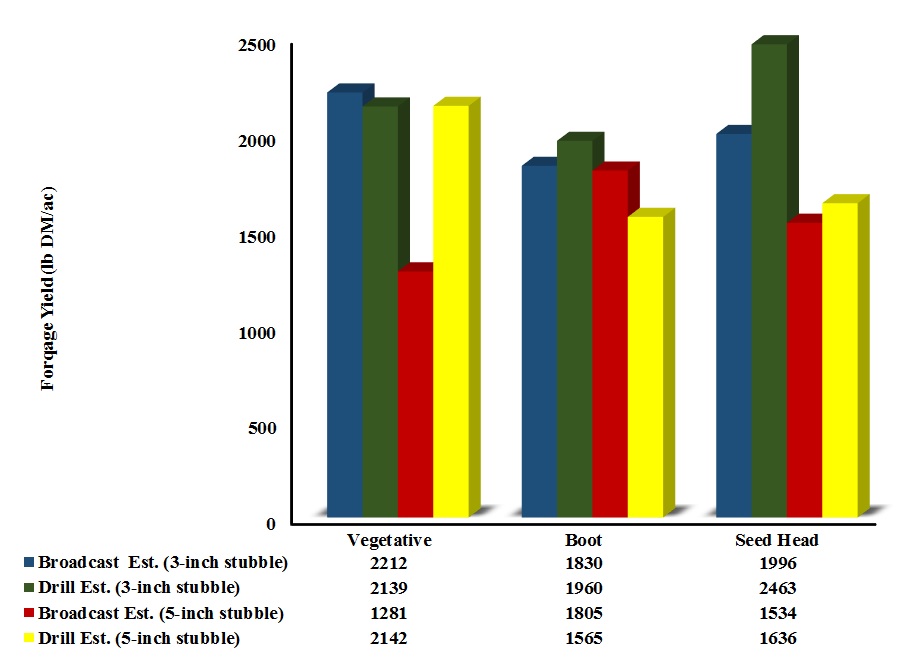

Precipitation and average temperature were below normal for the duration study (Table 1). Precipitation was 3 inches below normal in 2014 while temperatures were 10 ºF below normal. There was no significant difference between the establishment methods or harvested growth stages. However, drilling the seed producer 12% greater yield than the broadcast method (Fig. 3). There was a tendency to yield differences among the growth stages at α = 0.10 (P<0.0679). Harvesting at the vegetative growth stage (2,007 lb/ac) produced 20% greater yield than harvesting at the boot stage (1,659 lb/ac), but were similar to the seed head stage (1,975 lb/ac). There was a significant difference between cutting height (P<0.0023). Cutting at the three-inch stubble height yielded 27 % more biomass (2,100 lb/ac) than harvesting at a five-inch stubble height (1,660 lb/ac).

SUMMARY AND CONCLUSIONS

The performance of teff grass was measured across different environmental conditions and under different fertility regimes, harvest pressure at different growth stages and cutting heights across two studies. Despite of the treatments applied, teff grass had lower yields than those previously reported in the literature (Miller, 2011; Norberg et al., 2009; Marsalis and Lauriault, 2015). Yields in these studies are more aligned to those reported by White et al. (2011) under Mississippi conditions. There was a yield variability between cuts and nitrogen responses, but the variability was consistent. Based on the yield responses obtained during Study #1, there were some response to the added N, but N fertilization greater than 30 to 60 lb/ac cannot be justified. Teff grass could be planted earlier in mid-May to have maximum forage production by late July and allowing replanting for a second cropping season. Despite of this possible management strategy, it is important to note that environmental conditions for an August planting could be limited by drier conditions and high humidity and daytime temperatures. Irrigation could be an option during the late summer, but cannot be justified in the south based on yield potential. Cutting at boot stage and a three-inch stubble height should be the recommended harvest interval since delayed harvest did not affect forage yields, but could possibly impact nutritive value. Although teff grass has comparable yields to crabgrass, there is the reseeding potential advantage of crabgrass in subsequent years. In general, teff performed below the threshold yields reported in other parts of the country. This could be related to high temperature and humidity and sometimes prevailing rainfall limitations. The overall nutritive value of teff did not shift significantly between cutting or nutrient management. Overall teff quality was comparable to other warm-season annual grass such as crabgrass.

Teff grass makes excellent forage for horse and livestock, but the yield potential in the Mississippi is much lower than what is reported in the literature. Further research is needed to determine optimum planting dates, seeding rates, time and planting methods, cutting intervals, and fertilizer use efficiency that can increase biomass production and can provide an economic justification because yearly effects can impact pasture production in the southern USA. Further experiments under irrigation could be important to increase forage production in mid- to late summer under hot and humid conditions.

ACKNOWLEDGEMENT

This publication is a contribution of the “Mississippi Agricultural and Forestry Experiment Station (MAFES) and the Mississippi State University Extension Service (MSU-ES).” Thank you Allied Seed, LLC (Nampa, ID), Cal-West Seed (Woodland,CA) and Elstel Farm & Seeds (Ardmore, OK) for donating seed for this studies. Thank you to the student workers: Cory Davis, Parker Evans, Mark Langford, Daniel Moore, Isaac Pickett, Timothy Newman and W. Michael Hammack for helping with planting, data collection and sample preparation. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

DISCLAIMER

Mention of a trademark, proprietary product, or vendor does not constitute a guarantee or warranty of the product by Mississippi State University and does not imply its approval to the exclusion of other products or vendors that also may be suitable.

Literature Cited

Eckhoff, J.L.A., Wichman, D.M., Scheetz, J., Majerus, M. Welty, L.e., Stalknecht, G.F., Ditterline, R.L., and Dunn, R.L. (1993). Teff: a potential forage and grain crop for Montana. Montana AgResearch 10:38-41.

Holman, J.D., Min, D.H., adn Maxwell, S. (2015). Teff grass response to nitrogen fertilization. Kansas Agricultural Experiment Station Research Reports: Vol. 1(5). Retrieved from: http://dx.doi.org/10.4148/2378-5977.1078

Johnson, D.(2007). Teff grass, lovegrass, annual bunch grass, warm season annual bunch grass. Retrieved from: http://horsehints.org/TeffGrass.htm

Norberg, S., Roseberg, R.J., Charlton, B., and Shock, C. (2009). Teff, a new warm season grass for Oregon. Oregon State University Extension Service EM 8970-E. Retrieved from: http://library.state.or.us/repository/2008/200811050908063/index.pdf

Marsalis, M.A., and Lauriault, L.M. (2015). Teff hay: Recent observations in the southwest. In: Proceedings, 2015 Western Alfalfa and Forage Symposium, Reno, NV, 3-4 December.

Miller, D.R. (2011). Teff grass crop overview and forage production guide (third edition). Cal/West Seed Company, Woodland, CA. http://www.calwestseeds.com/products/teff/

Roseberg, R.J., Norberg, S., Smith, J., Charlton, B., Rykbost, K., and C. Shock. (2006). Yield and quality of teff forage as a function of varying rates of applied irrigation and nitrogen. In: Research in the Klamath Basin 2005 Annual Report 1069: 119-136. Retrieved from: http://oregonstate.edu/dept/kbrec/sites/default/files/documents/hort/teff.pdf

SAS Institute. (2016). SAS Enterprise user's guide. Version 9.4. SAS Institute, Inc. Cary, NC.

White, J.A., Lemus, R., Lang, D., and Morrison, J.I. (2011). Mississippi warm-season forage crop variety trials, 2011. Mississippi Ag. and Fores. Exp. Stn. IB0467. Retrieved from: http://mafes.msstate.edu/publications/information-bulletins/ib0467.pdf

White, J.A., Lemus, R., Saunders, J.R., and Fitzgerald, L. (2013). Mississippi warm-season forage crop variety trials, 2012. Mississippi Ag. and Fores. Exp. Stn. IB0474. Retrieved from: http://mafes.msstate.edu/publications/information-bulletins/ib0474.pdf

Tables and Figures

| Growing Period1 | Precip | Dep | GDD2 | Dep | Temp | Dep | ||

| --------- inches --------- | --------- oF --------- | |||||||

| 2010 | 13.7 | -6.1 | 3826 | 448 | 82.0 | -6.3 | ||

| 2011 | 13.4 | -6.4 | 3677 | 299 | 79.7 | -8.7 | ||

| 2014 | 16.7 | -3.1 | 3380 | 2 | 78.6 | -9.8 | ||

| LTA | 19.8 | -- | 3378 | -- | 88.4 | -- | ||

|

1Each period represents the implementation of the stockpiling study from May to August. 2Growing degree days base 50. |

||||||||

| Year | ||

| Nitrogen Rate (lb/ac) | 20102 | 20113 |

| --------------------- Biomass (lb DM/ac) --------------------- | ||

| 0 | 3035 | 1526 |

| 30 | 3027 | 1773 |

| 60 | 3596 | 1860 |

| 60S1 | 3160 | 1753 |

| 90 | 3477 | 1608 |

| 90S1 | 3524 | 1856 |

| Mean | 3303 | 1729 |

| LSD0.05 | 351 | NS |

| CV (%) | 11 | 27 |

|

1Indicates split N applications. 2Seasonal yield from a two cut system. 3Yield from only one cut. |

||

| Year | |||

| Forage Species | Cultivar | 2010 | 2011 |

| -------------- Biomass (lb DM/ac) -------------- | |||

| Crabgrass | 'Quick-N-Big' | 3125 | 1654 |

| 'Red River' | 3193 | 1634 | |

| Teff grass | 'Dessie' | -- | 1781 |

| 'Tiffany' | 3591 | 1849 | |

| Mean | 303 | 1729 | |

| LSD0.05 | 248 | NS | |

| Harvest Date | |||

| Cultivar | July 19 | August 26 | LSD0.05 |

| ------------------ ADF (%) ------------------ | |||

| 'Quick-N-Big' crabgrass | 35.6 | 36.1 | NS |

| 'Red River' crabgrass | 34.3 | 37.3 | 1.8 |

| 'Tiffany' teff grass | 34.0 | 36.6 | 1.2 |

| LSD0.05 | 0.7 | NS | -- |

| ------------------ NDF (%) ------------------ | |||

| 'Quick-N-Big' crabgrass | 58.4 | 61.0 | 2.0 |

| 'Red River' crabgrass | 55.6 | 61.1 | 2.9 |

| 'Tiffany' teff grass | 61.4 | 63.0 | NS |

| LSD0.05 | 1.1 | NS | -- |

| ------------------ WSC (%) ------------------ | |||

| 'Quick-N-Big' crabgrass | 3.7 | 4.9 | 1.0 |

| 'Red River' crabgrass | 4.0 | 4.1 | NS |

| 'Tiffany' teff grass | 5.5 | 4.5 | 0.9 |

| LSD0.05 | 0.6 | NS | -- |

Figure 1. Impact of nitrogen rate on acid detergent fiber concentration of warm-season annual grasses in Starkville, MS during the 2010 growing season. Data averaged over two crabgrass cultivar and one teff grass cultivar.

Figure 2. Impact of nitrogen rate on acid detergent fiber concentration of warm-season annual grasses in Starkville, MS during the 2010 growing season. Data averaged over two crabgrass cultivar and one teff grass cultivar.

Figure 3. Seasonal yield distribution of ‘Tiffany’ teff grass across two establishment methods, three growth stages and two cutting heights.