Journal of the NACAA

ISSN 2158-9429

Volume 12, Issue 1 - June, 2019

Generating Data-Based Recommendations for Pastured Broiler Producers

- Knight, C. , State Livestock Specialist, University Of Maine Cooperative Extension

Anderson, G., Animal and Bioscience Specialist, University of Maine Cooperative Extension

Hatley, J. , Director J. F. Witter Teaching and Research Center, University of Maine

ABSTRACT

An increasing number of small farms are including pastured broiler production into their business model in Maine. However, few science and data driven studies are available to help producers make management decisions. In order to help the University of Maine Cooperative Extension, a field trial was conducted. The objective of this trial was to look at growth rate, feed efficiency, feed intake, water use, forage utilization, carcass traits, and mortality data on 5 slow-growing breeds and 1 conventional breed of broilers on pasture. Chicks arrived from the hatchery 5-6 June 2017, and were immediately placed into a brooder room (24.4-32.2 °C) based on breed until they had sufficient plumage to be moved to the chicken tractor. After a 5 d acclimation period, tractors were moved to a recently mowed Timothy-grass hay pasture (Phleum pretense). Tractors were moved daily to fresh grass, and daily pen feed intake, water use, and forage utilization monitored. In addition, birds were weighed weekly, and prior to and after processing to determine dressing percentages and carcass weights. On average, birds on pasture consumed 4.68 kg of feed during their lifetime, used 10.92 L of water, and forage utilization averaged 45%.

Introduction

In January 2017, the National Chicken Council released an article supporting the U.S. Poultry and Egg Association on the need for funded research of slow growing poultry (National Chicken Council, 2017). The article also expressed the need for science and data based studies versus emotional or rhetoric based conclusions on poultry welfare and growth rates. Maine has no registered commercial broiler operations, but the 2012 USDA Census of Agriculture reports that farmers in Maine produce approximately 55,657 broilers (meat birds) annually, an increase of 281% from 2007 (USDA, 2014). This illustrates that broilers are produced on small-scale farming operations, which are sold mostly through farmers markets and community supported agriculture (CSA) ventures. Over that same five-year period, small-scale farm operations increased 65% from 214 to 355 farms in Maine (USDA, 2014).

Many farmers are venturing into small-scale pastured poultry models with little to no science-based guidance. The majority of farmers are developing production practices through trial and error methods. The current lack of data on starting a pastured broiler operation creates a lot of uncertainty for beginning farmers. The objectives of this study were to compare conventional, slow growing and heritage breeds of pastured broilers for growth rate, water use, forage utilization, feed intake and efficiency, mortality rates, and dressing percentages in order to make recommendations for producers.

Materials and Methods

Animal Care and Use

Experimental protocols were approved for all animals by the University of Maine Institutional Animal Care and Use Committee. Six strains of broilers were utilized in this study. First, a conventional Cornish Rock Cross (CC, n = 32) was selected to serve as a control. Four commonly utilized slow growing breeds were selected based on popularity and availability for this study. Those breeds included: Red Freedom Ranger (RF, n = 32), Black Freedom Ranger (BF, n = 32), Imperial Red (IR, n = 30) and Imperial Stripe (IS, n = 30). Finally, Turken “Naked” Neck (TN, n = 32) birds were selected for comparison for their popularity in Western Europe because of reported ease of plucking and heat resistance. Turken Neck chicks were hatched 5 June 2017 while the remaining breeds were hatched on 6 June, 2017. Chicks were delivered to the University of Maine’s J. Franklin Witter Center in Orono, ME between 7-8 June 2017. Upon arrival, chicks were randomly placed in one of six brooders (24.4 - 32.2 °C) based on breed. Broilers were fed a 20% chick starter (Poulin Grain, Newport, VT). Initially, birds were fed from flat pans and jar-style feeders and water offered in jar-style waterers. Chicks were kept in brooders until they grew sufficient plumage to be moved to chicken tractors (~14 d). Cornish Rock Cross, IR, and IS birds were obtained from Moyer Hatchery (Quakertown, PA), RF and BF breeds from Freedom Ranger Hatchery (Reinholds, PA), and TN from Purely Poultry (Fremont, WI).

On 18 June 2017 birds were moved to chicken tractors placed inside a covered barn and given a heat lamp to aid in acclimation of the new environment. Jar-style waterers and feeders were replaced with 13.6 kg gravity feeders and 18.9 L pails fitted with 4 watering nipples. Chick starter feed was replaced with 20% broiler crumble (Poulin Grain, Newport, VT). After a 4 day acclimation period, tractors were moved to pasture. Temperature, humidity, feed utilization, and water utilization were monitored daily while animals were in the brooder. Weekly brooder weights were also collected. Prior to being moved to pasture, broiler numbers were reduced (n = 28) per tractor to maintain an even stocking rate. Once broilers were moved to the tractor, daily feed, water and forage utilization per tractor were monitored. Each tractor was equipped with a high/low temperature and humidity sensor. Individual weights were collected weekly once chicks were placed on pasture. Broilers remained on pasture until the tractor average weight per bird was 2.38 kg.

Table 1. Nutrient analysis of chick starter crumble.

|

Minimum |

Maximum |

|

|

Crude Protein,% |

20.0 |

|

|

Lysine, % |

1.0 |

|

|

Methionine,% |

0.4 |

5.0 |

|

Crude Fat,% |

3.0 |

|

|

Crude Fiber, % |

5.0 |

|

|

Calcium, % |

0.9 |

1.2 |

|

Phosphorus, % |

0.6 |

|

|

Salt |

0.3 |

0.5 |

|

|

|

|

Table 2. Nutrient analysis of broiler crumble.

|

Minimum |

Maximum |

|

|

Crude Protein,% |

20.00 |

|

|

Lysine, % |

1.05 |

|

|

Methionine,% |

0.35 |

|

|

Crude Fat,% |

3.00 |

|

|

Crude Fiber, % |

5.00 |

|

|

Calcium, % |

0.95 |

1.20 |

|

Phosphorus, % |

0.60 |

|

|

Salt |

0.30 |

0.50 |

|

|

|

|

|

|

|

Chicken Tractors

On 26 June 2017 all tractors were moved from the covered barn and placed on a recently mowed Timothy-grass hay pasture (Phleum pretense). Breeds were randomly assigned one of six lanes and placed 1 m apart. The tractor was advanced the length of itself daily to allow the birds fresh foraging material. After one week, tractors rotated lanes weekly to reduce environmental effects. Feed and water consumption was recorded daily. Tractor temperature and humidity were monitored daily. Also, daily forage utilization was calculated.

Figure 1. Suscovich-style chicken tractors used during this study (Suscovich, 2016). Total material cost per tractor were $319.97.

Forage Utilization

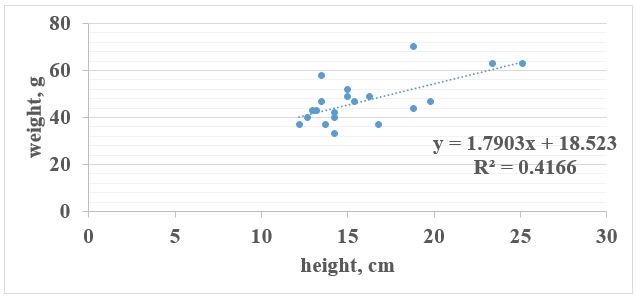

Forage utilization is defined as the proportion of current year’s forage production that is consumed or destroyed by grazing animals (USDA, 2012). Gathering forage utilization data can help calculate a rough estimate of forage intake. Forage utilization was estimated based on the height-weight method described by Lommasson and Jensen (1943). On four separate dates during the summer of 2017, forage heights and weights were collected. A 40 x 40 cm frame was placed around five random locations within the study field (outside the tractors) and an average forage height was recorded. Then, all forage within the frame was clipped, weighed, and dried in a 60 °C drying oven until weights stabilized. A basic linear regression model was used to fit forage height with weight (dry matter). During the trial, a 10 point grid was setup within the dimensions of the chicken tractor. Forage heights were taken at each point within the grid before and after the tractor grazed each location with a meter stick. Heights were averaged before and after to estimate forage availability and utilization.

Results and Discussion

Forage height and weight measurements are shown in Table 3. The linear regression model used to calculate forage availability is shown in Figure 1.

Table 3. Forage Calibration

|

Frame |

||||||||||

|

Sample |

||||||||||

|

6/23/2017 |

1 |

2 |

3 |

4 |

5 |

Average, in |

Avg, cm |

DM, % |

Forage, g |

|

|

1 |

4.5 |

4.0 |

4.5 |

7.0 |

6.5 |

5.3 |

13.5 |

32.4 |

47.0 |

|

|

2 |

5.0 |

5.0 |

4.5 |

6.0 |

5.5 |

5.2 |

13.2 |

36.1 |

43.0 |

|

|

3 |

5.5 |

4.0 |

5.0 |

6.0 |

6.0 |

5.3 |

13.5 |

39.7 |

58.0 |

|

|

4 |

4.5 |

3.5 |

5.0 |

6.0 |

6.5 |

5.1 |

13.0 |

33.1 |

43.0 |

|

|

5 |

5.0 |

5.0 |

6.0 |

6.0 |

6.0 |

5.6 |

14.2 |

43.3 |

42.0 |

|

|

6/30/2017 |

||||||||||

|

1 |

5.0 |

6.0 |

6.0 |

7.0 |

5.5 |

5.9 |

15.0 |

35.5 |

49.0 |

|

|

2 |

5.0 |

6.0 |

11.0 |

5.0 |

5.0 |

6.4 |

16.3 |

44.1 |

49.0 |

|

|

3 |

6.0 |

5.5 |

6.0 |

6.0 |

6.0 |

5.9 |

15.0 |

40.9 |

52.0 |

|

|

4 |

5.0 |

6.4 |

6.0 |

6.0 |

7.0 |

6.1 |

15.4 |

34.6 |

47.0 |

|

|

5 |

9.0 |

6.0 |

11.0 |

8.0 |

12.0 |

9.2 |

23.4 |

40.4 |

63.0 |

|

|

7/7/2017 |

||||||||||

|

1 |

8.0 |

6.0 |

8.0 |

9.0 |

6.0 |

7.4 |

18.8 |

35.9 |

70.0 |

|

|

2 |

6.0 |

8.0 |

8.0 |

9.0 |

6.0 |

7.4 |

18.8 |

32.1 |

44.0 |

|

|

3 |

6.0 |

9.0 |

6.0 |

9.0 |

9.0 |

7.8 |

19.8 |

37.6 |

47.0 |

|

|

4 |

7.5 |

7.5 |

8.5 |

14.0 |

12.0 |

9.9 |

25.1 |

33.9 |

63.0 |

|

|

5 |

9.0 |

6.0 |

5.0 |

7.0 |

6.0 |

6.6 |

16.8 |

34.3 |

37.0 |

|

|

7/14/2017 |

||||||||||

|

1 |

4.0 |

7.0 |

6.0 |

5.0 |

5.0 |

5.4 |

13.7 |

31.1 |

37.0 |

|

|

2 |

5.0 |

5.0 |

8.0 |

5.0 |

5.0 |

5.6 |

14.2 |

24.4 |

33.0 |

|

|

3 |

5.0 |

6.0 |

6.0 |

3.0 |

4.0 |

4.8 |

12.2 |

30.8 |

37.0 |

|

|

4 |

6.0 |

7.0 |

5.0 |

4.0 |

6.0 |

5.6 |

14.2 |

28.2 |

40.0 |

|

|

5 |

4.0 |

7.0 |

6.0 |

4.0 |

4.0 |

5.0 |

12.7 |

29.2 |

40.0 |

|

Figure 2. Linear regression model used to calibrate forage availability of chickens on timothy grass pasture.

Table 4 illustrates the basic summary production data for the project. Turken necks (TN) were removed from the trial during week 9 due to very slow growth rates. Lifetime water use per bird appeared highest for IR when compared with RF, BF, CC and IS. Average individual feed consumption was similar across breeds, ranging from 4.1 to 5 kg. Cornish Rock Cross birds were processed at 46 days old, RF and IS at 60, BF at 61, and IR at 62 days. Live weights of birds did not differ (P > 0.05) among breeds at slaughter. However, CC birds had a higher (P < 0.05) dressing percentage (75%), compared with the other breeds (68±3%), yielding approximately 202 g more per carcass. Gain appeared similar for all groups (2.94±0.24). No differences in forage utilization were apparent among breeds (10.6±6.9 g/d). While forage utilization was similar across breeds, the CC tractor required 71-82 m2 less land than RF, BF, IR and IS tractors due to shorter growth period. No lameness or breast abrasions were observed across breeds.

Comparing these data with the average expected performance of Arbor Acres Plus commercial broilers in a controlled atmospheric house shows the house birds grew faster and were more efficient. House birds were at the pasture bird slaughter weight by 29 days of life compared with our Cornish Cross birds at 46 days and the other breeds by day 60-62 (Arbor Acres Plus Broiler Performance Objectives, 2014). Feed Conversion Ratio (FCR) of our pasture birds (3.6 for CC birds) was much lower than the Arbor Acres Plus house birds at 1.4 kg of feed per kg of gain. Our slow grow birds had lower FCR compared with our CC birds at 3.9 to 4.8 kg of feed per kg of gain. According to a University of Kentucky factsheet (Jacob and Pescatore, 2012) expected lifetime feed intake of conventionally raised broilers is 4.65 kg. Feed intake for our control CC, RF, and IR birds were slightly higher at 4.8, 5.0, and 4.9 kg, respectively. However, our BF and IS broilers appeared to be lower with 4.1 and 4.6 kg, respectively.

Table 4. Results of the University of Maine Pasture broiler field trial. Feed intake is lifetime grain intake (90% dry matter). Means within a row with different superscripts are statistically different (P < 0.05). FCR (feed conversion ratio) is defined as feed:liveweight gain. FCRcarcass is defined as feed:carcass weight.

|

University of Maine - Pasture Poultry Project |

|||||

|

|

|||||

|

Breed |

|||||

|

Cornish Cross |

Red Freedom Ranger |

Black Freedom Ranger |

Imperial Red |

Imperial Stripe |

|

|

|

|

|

|

|

|

|

N |

28 |

28 |

28 |

28 |

28 |

|

Feed Intake, kg* |

4.8 |

5.0 |

4.1 |

4.9 |

4.6 |

|

Water Use, L |

10.7 |

10.7 |

10.1 |

12.5 |

10.6 |

|

Forage Utilization, kg |

0.3 |

0.3 |

0.4 |

0.3 |

0.4 |

|

Forage Utilization, % |

51 |

44 |

46 |

44 |

40 |

|

FCR** |

2.7 |

3.0 |

2.7 |

2.9 |

3.2 |

|

FCRcarcass*** |

3.6 |

4.3 |

3.9 |

4.2 |

4.8 |

|

Death Loss, % |

0.0A |

0.0A |

3.6A |

3.6A |

0.6A |

|

Mobility/leg issues, % |

0.0 |

0.0 |

0.0 |

0.0 |

0.0 |

|

Abrasions, % |

0.0 |

0.0 |

0.0 |

0.0 |

0.0 |

|

|

|

||||

|

|

Processing Data |

||||

|

|

Cornish Cross |

Red Freedom Ranger |

Black Freedom Ranger |

Imperial Red |

Imperial Stripe |

|

|

|

|

|

|

|

|

N |

28 |

28 |

27 |

27 |

27 |

|

Live Weight, kg |

2.5A |

2.5A |

2.3A |

2.5A |

2.4A |

|

Carcass, kg |

1.9A |

1.7AB |

1.6B |

1.7B |

1.6AB |

|

Dressing,% |

75A |

69B |

68B |

68B |

67B |

Authors observed no structural issues or breast abrasions in either slow-growing breeds or the conventional CC birds during this trial, suggesting that birds slaughtered at a liveweight of 2.5 kg can support their own weight while maintaining a higher performance level. Since CC reach slaughter weight approximately 2 weeks prior to slow growing birds, they were only being moved on pasture for 3 weeks compared with slow growing birds which require moving the tractor for 5 weeks. Given Maine’s climate, a four month production cycle could be utilized from mid-May to mid-September. Producers could run 3 full production cycles of CC versus only 2 of slow growing breeds. Cornish cross birds take 46 days for their first production cycle, but then only 28 days on pasture for subsequent CC birds. Two batches of birds could be completed in 74 days, 3 batches in 102 days. Slow growing birds would require 60 days for one cycle, 102 for two batches and 144 days for 3.

In order to maintain healthy pastures, it is a good idea to only remove ~50% of the forage. Once more than 50% of the biomass is removed above ground, the plant root structure starts to suffer which leads to a decline in pasture health (Crider, 1955; Johnson, 1961). During the first week on pasture, breeds averaged a 9% forage utilization per day, so during the first week on pasture, birds would only have to be moved about two times a week to maintain a healthy pasture. After the first week, authors recommend moving the tractors daily because forage utilization averages approximately 50%. If a larger carcass size is desired, tractors may need to be moved more frequently thereafter. During hotter weather, birds tended to lie down more, and their forage utilization went down significantly. In order to reduce heat stress on birds, it would be a good practice to only move the tractors every other day while experiencing above average temperatures. Table 5 provides recommendations on acreage needed to raise pastured broilers.

Generally speaking, livestock tend to trample as much forage as they consume. However, most livestock have anatomy conducive to digesting cellulose (the most abundant form of energy on Earth), like ruminants or horses. Chickens are not able to digest cellulose (a structural component of plant cell walls), so they probably consume an even smaller percentage of forage than ruminants or horses. Even if chickens did consume an equal percentage of the forage utilized, it would only make up 3.6% of their diet. Authors would assume that intake would be slightly higher on a legume based pasture, but would most likely make no significant difference. Often times, farmers assume that poultry raised on pasture will consume less feed over their production cycle when compared with house raised poultry due to foraging for grass and insects. However, this is not true. Animals will have a higher energy demand living outside because they are expending more energy walking around and using more energy to stay warm/cool.

Authors are unaware of any previous attempts to characterize forage utilization in broilers housed in tractors. However, three attempts were made on free-ranging broilers. Riverra-Ferra et al. (2007) reported an average DMIforage (forage dry matter intake) of 10.5 – 11.0 g per day per bird depending on shelter type, where as birds on this study utilized 11.29-15.07 g per day per bird. Authors expect actual DMIforage to be less than half of forage utilization. The aforementioned study was based on a legume (clover) pasture, which could explain the discrepancy. Bosco et al. (2014) reported an average DMI of 14.80 grams per day per bird on unspecified forage paddocks in Spoleto, Italy. A study by Ponte et al. (2008) estimated forage intake between 2.5 - 4.5%, which falls directly in line with our estimate of 3.6%.

Table 5. Approximate acreage needed for pasture poultry production.

|

Cornish Cross |

||||||

|

Chickens per tractor |

Tractor |

Days |

Acres |

Chicken capacity |

Reps |

Total Acreage |

|

|

|

|

|

|

|

|

|

36 |

1 |

21 |

0.16 |

216 |

1 |

0.16 |

|

36 |

1 |

21 |

0.16 |

432 |

2 |

0.32 |

|

36 |

1 |

21 |

0.16 |

648 |

3 |

0.48 |

|

36 |

3 |

21 |

0.16 |

216 |

1 |

0.48 |

|

36 |

3 |

21 |

0.16 |

432 |

2 |

0.95 |

|

36 |

3 |

21 |

0.16 |

648 |

3 |

1.43 |

|

36 |

6 |

21 |

0.16 |

216 |

1 |

0.95 |

|

36 |

6 |

21 |

0.16 |

432 |

2 |

1.91 |

|

36 |

6 |

21 |

0.16 |

648 |

3 |

2.86 |

|

Slow growing |

||||||

|

|

|

|||||

|

36 |

1 |

35 |

0.27 |

216 |

1 |

0.27 |

|

36 |

1 |

35 |

0.27 |

432 |

2 |

0.53 |

|

36 |

1 |

35 |

0.27 |

648 |

3 |

0.80 |

|

36 |

3 |

35 |

0.27 |

216 |

1 |

0.80 |

|

36 |

3 |

35 |

0.27 |

432 |

2 |

1.59 |

|

36 |

3 |

35 |

0.27 |

648 |

3 |

2.39 |

|

36 |

6 |

35 |

0.27 |

216 |

1 |

1.59 |

|

36 |

6 |

35 |

0.27 |

432 |

2 |

3.18 |

|

36 |

6 |

35 |

0.27 |

648 |

3 |

4.77 |

Death loss during this trail is attributed to injured birds. Initially, chicks do not know to move away from the tractor when it is being advanced forward. Their legs can easily get caught in the tractor. When first moving the tractor, one person should flush the chicks forward while another advances the tractor forward. Once trained, birds will naturally move to the front of the tractor while it is being moved. Tractors should also be set in a staggered pattern, overlapping slightly to utilize forage evenly, and prevent excessive humidity and temperature build up in the center tractors. Authors prefer taller style chicken tractors, like used in this study, because people can easily walk in and out to change feed and water. Feeders and waterers can be hung from the ceiling to help prevent spillage from the birds, and they stay cleaner being off the ground. The taller structure allows for good airflow, and the tarp used for sun/rain protection sits higher over the birds head, helping prevent radiant heat stress.

Carcasses from all birds on this study were retained for taste and palatability tests. However, freezer damage during a storm ruined half the samples collected, leaving too few numbers to conduct an accurate test. On an anecdotal note, authors observed no taste difference among CC, RR, BR, or IR birds. Imperial Stripe birds were noticeably tougher to chew and had a different flavor. Black Freedom Rangers had a purple tint to their skin and dark pin feathers. This coloration could lead consumers to believe the meat was bruised or not fresh. Producers raising Black Freedom Rangers would need to educate their consumers if they expect the general public to accept these birds.

Literature Cited

Arbor Acres Plus Broiler Performance Objectives. (2014). Aviagen Company Publication. Retrieved from: http://en.aviagen.com/assets/Tech_Center/AA_Broiler/AA-Broiler-PO-2014-EN.pdf

Bosco, A. D., Mugnai, C., Rosati, A., Paoletti, A., Caporali, S., and Castellini, C. (2014). Effect of range enrichment on performance, behavior, and forage intake of free-range chickens. The Journal of Applied Poultry Research, 23(2):137-145. doi:10.3382/japr.2013-00814

Crider, F. J. (1955). Root-growth stoppage: Resulting from defoliation of grass. Washington, DC: U.S. Dep. of Agriculture.

Jacob, J., and Pescatore, T. (2012). How much will my chickens eat? Publication No. ASC-191. University of Kentucky Cooperative Extension Service. Lexington, KY: doi:http://www2.ca.uky.edu/agcomm/pubs/asc/asc191/asc191.pdf

Johnston, A. (1961). Comparison of lightly grazed and ungrazed range in the fescue grassland of southwestern Alberta. Canadian Journal of Plant Science 41(3):615-622. doi:10.4141/cjps61-090

Lommasson, T. and C. Jenson. (1943). Determining utilization of range grasses from height-weight tables. Journal of Forestry 41(8):589-593.

National Chicken Council. (2017). National Chicken Council calls for balance between animal care, environmental, economic impact in chicken production. Retrieved from: https://www.nationalchickencouncil.org/national-chicken-council-calls-balance-animal-care-environmental-economic-impact-chicken-production/.

Ponte, P. I., Rosado, C. M., Crespo, J. P., Crespo, D. G., Mourao, J. L., Chaveiro-Soares, M. A., and Fontes, C. M. (2008). Pasture intake improves the performance and meat sensory attributes of free-range broilers. Poultry Science 87(1):71-79. doi:10.3382/ps.2007-00147

Rivera-Ferre, M. G., Lantiga, E. A., and Kwake, R. P. (2007). Herbage intake and use of outdoor area by organic broilers: Effects of vegetation type and shelter addition. NJAS – Wageningen Journal of Life Sciences 54(3):279-291. https://doi.org/10.1016/S1573-5214(07)80020-0

Suscovich, John. (2016). Stress-Free Chicken Tractor Plans: An Easy to Follow, Step-By-Step Guide to Building Your Own Chicken Tractors. 2nd Ed. Farm Marketing Solutions. Emerald Lake Books.

United States Department of Agriculture. (2014). Retrieved from https://www.nass.usda.gov/Publications/AgCensus/2012/

USDA. (2012). Harvest Efficiency in Prescribed Grazing. Technical Note 73. Boise, ID – Salt Lake City, UT. pp. 589-593.